Structured Improvement

What Is Structured Improvement?

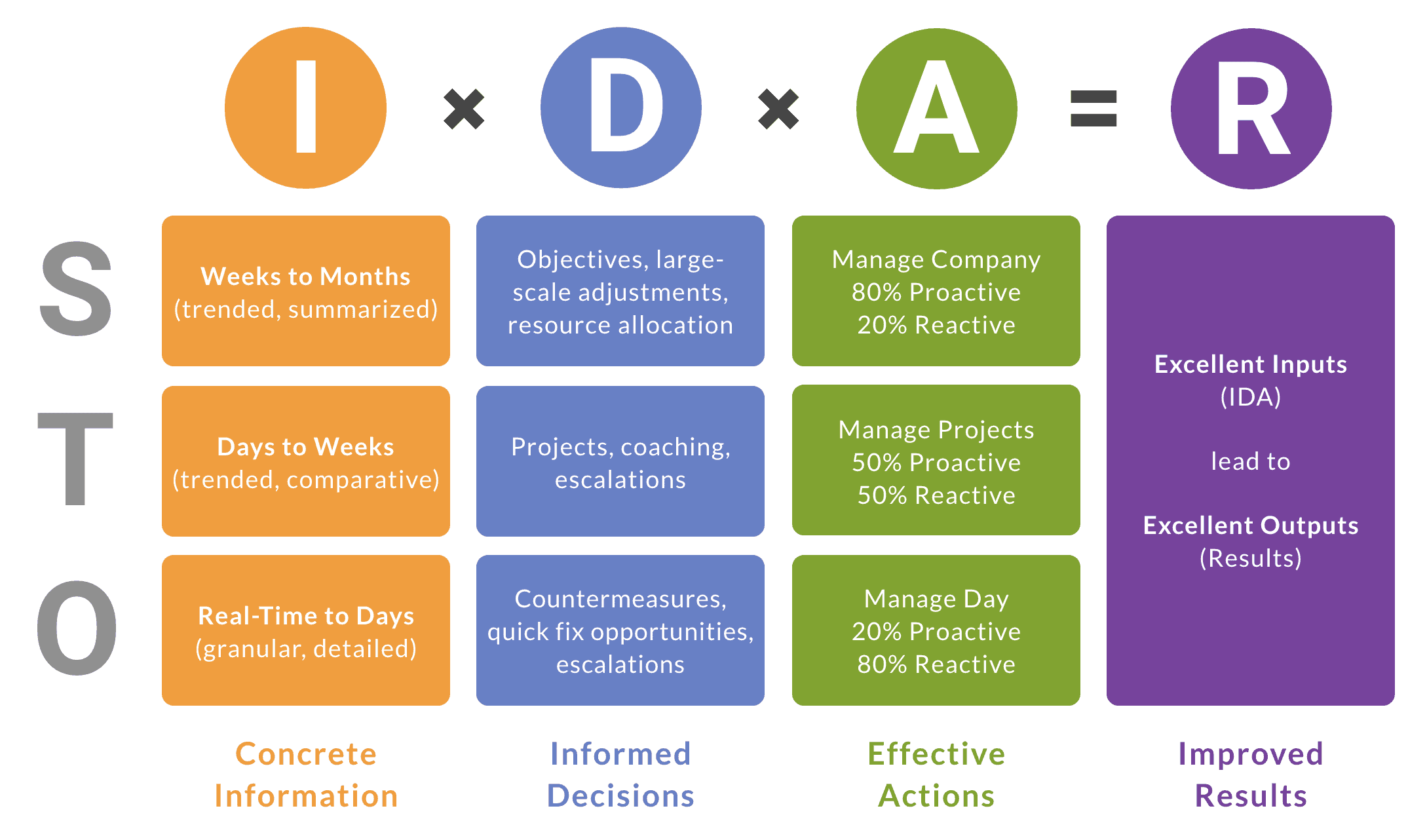

Structured Improvement facilitates sustained improvement, by aligning people, information, decisions, and actions to the same objective.

IDA and the Structured Improvement Process

The process is straightforward:

- Define a clear improvement objective.

- Connect strategic, tactical, and operational improvement meetings that are tied to the objective.

- Use concrete and accurate information in these meetings to make informed decisions that lead to effective actions.

Connecting meetings facilitates coordinated actions:

- At a strategic level, executives define the objective, monitor progress towards the objective, and allocate corporate resources.

- At a tactical level, managers define and manage projects that drive progress towards the objective, as well as escalate issues that need special attention.

- At an operational level, supervisors and operators proactively make incremental improvements and reactively respond to emerging issues.

Why Use Structured Improvement?

Many companies rely on the intuition of managers, supervisors, and operators to identify actions to drive improvement. The problem with this approach is that there is no repeatable and sustainable process, and actions are typically isolated and very dependent on the skills of the individual.

Structured Improvement is scalable and sustainable. It is a standardized work process that facilitates consistent and repeatable decision-making and aligned actions at each level of the organization.

Structured Improvement Process

Define Objective

The first step is to define a business objective. There is a simple set of questions that should be answered. What will be improved? Over what time frame? How will this help our business? What is the desired result? Is it attainable? What KPIs will be used to measure progress?

Define and Connect Meetings

The second step is to define a set of connected meetings that will drive progress. One of the most appealing aspects of Structured Improvement is that it explicitly sets out to minimize the number and scope of meetings. It’s not about more meetings – it’s about devising the smallest number of meetings that will effectively drive meaningful action.

Define and Connect Reports

Although it is important for people at all levels to make decisions and take actions based on the same underlying information, the optimal presentation, scope, and time horizon of that information will differ by level.

| Level | Description |

|---|---|

| Strategic | Trended and summarized information with a time horizon of weeks to months (e.g., OEE Trend by Department) |

| Tactical | Trended and comparative information with a time horizon of days to weeks (e.g., Six Big Losses by Shift) |

| Operational | Granular and detailed information with a time horizon of real-time to days (e.g., Down Time Events for One Line). |

Benefits of Utilizing Structured Improvement

In the short term, Structured Improvement aligns the team to more effectively deliver a specific improvement objective.

In the long term, Structured Improvement creates a sustained and repeatable focus on key objectives across all levels of the business.

Team Member Roles

Structured Improvement involves the following roles:

| Role | Description |

|---|---|

| Executive | Strategic. Sets and monitors objectives. Allocates resources. Reinforces process through occasional participation in team meetings. |

| Manager | Tactical. Translates vision and objectives into improvement projects. Manages projects. Removes impediments. Handles escalated problems. |

| Supervisors and Operators | Operational. Drives progress on day-to-day basis. Evaluates information in real-time to make continual mid-course adjustments. |

Key Insights for Structured Improvement

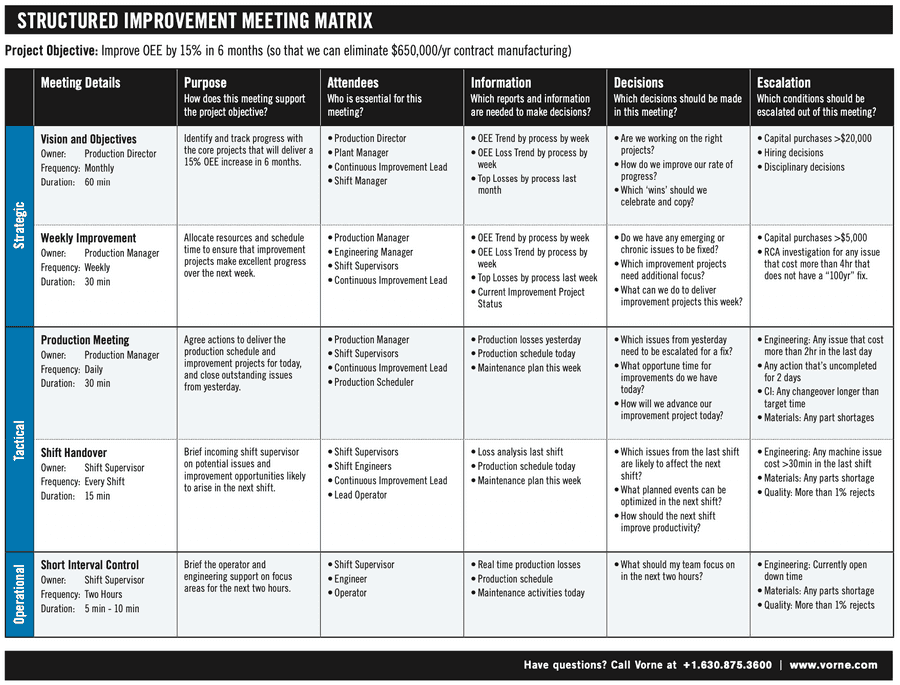

Structured Meeting Matrix Template

Take the red pill and enter The Matrix – the Meeting Matrix. The Meeting Matrix is a table, where each row represents a meeting and each column represents a key facet of that meeting.

- Rows might be Vision and Objectives (monthly), Weekly Improvement (weekly), Production Meeting (daily), Shift Handover (every shift), and Short Interval Control (every two hours).

- Columns might be Meeting Details, Purpose, Attendees, Information, Decisions, and Escalation.

The Meeting Matrix makes it easier to see how well a given objective is aligned across levels of the company, and to adjust as needed to ensure there is an effective framework for Structured Improvement.

Work Top-Down and Bottom-Up

Always start with a clear objective, supported with carefully selected KPIs. Then validate from top-down AND from bottom-up.

- From top-down, ensure all meetings are aligned to the top-level objective. Clearly define the function of each meeting towards delivery of that objective. Eliminate meetings that do not add significant value. Add meetings where there are large gaps.

- From bottom-up, ensure that the same underlying set of information is used, but presented in the most effective way to support the meeting. Also define when outliers or unresolved issues should be formally escalated to the next level up.

Start With a Simple Framework

Structured Improvement includes an optional predesigned framework for improving manufacturing productivity that consists of:

- Top Losses for managers

- Short Interval Control for supervisors and operators

Balance the Scorecard

When creating a Structured Improvement process, support the objective with a balanced scorecard that includes primary and secondary KPIs, and exception indicators.

Consider an automotive dashboard from a balanced scorecard perspective. It combines primary KPIs (Speed, RPM), secondary KPIs (Engine Temperature, Fuel Level), and exception indicators (Tire Pressure, Low Oil Warning).

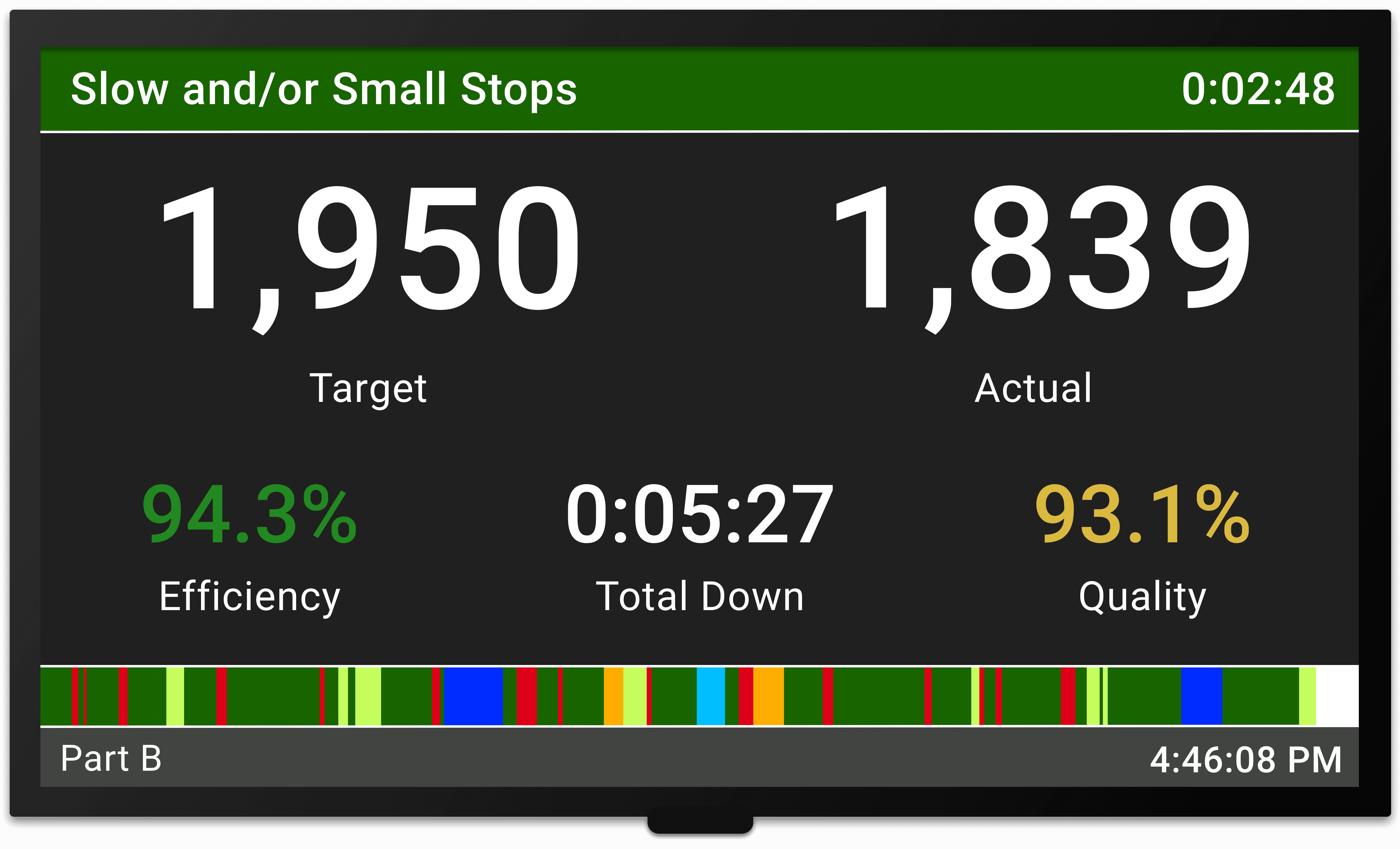

Align With Visual Cues

A highly effective way to align levels is to provide visual cues. For example:

- At a strategic level post the objective and Meeting Matrix in common areas.

- At a tactical level use a whiteboard to show the status of improvement projects.

- At an operational level use a scoreboard at the manufacturing process to show real-time and contextual metrics.

Relate to Policy Deployment

Structured Improvement is a close relative of Policy Deployment (also referred to as Hoshin Kanri). Policy Deployment aligns the goals of the company (Strategy), with the plans of middle management (Tactics) and the work performed on the plant floor (Operations). It ensures that progress is consistent and thorough – eliminating the waste that comes from poor communication and inconsistent direction.

So why Structured Improvement? Because it is purpose-specific. It has a significantly narrower scope, which makes it faster and easier to implement. It is designed to deliver a specific objective (e.g., improve OEE) through a series of tightly focused and connected meetings that use information to drive decisions, actions, and results.

Level and Difficulty

The Level is Intermediate. Structured Improvement is appropriate for organizations that have a solid information infrastructure, strong leadership, and a proven track record of following process.

The Difficulty is Moderate. There is an art to creating an effective set of connected meetings, and it takes a considerable amount of leadership support, training, and coaching to embed the behaviors necessary for effective decision-making and follow-through on actions.

Rate Yourself on Structured Improvement

How good are you at Structured Improvement? Answer ten simple questions to see how close you are to a model implementation.

| Question | ✔ |

|---|---|

| 1. Does your improvement project have a well-defined objective? | |

| 2. Has a time frame been established for meeting the objective? | |

| 3. Have KPIs been defined that are well-aligned to the objective? | |

| 4. Is a balanced scorecard used to further support the objective? | |

| 5. Has a Meeting Matrix been created and posted? | |

| 6. Has the Meeting Matrix been validated top-down and bottom-up? | |

| 7. Do managers have a framework for improvement projects? | |

| 8. Do supervisors and managers have an escalation framework? | |

| 9. Do operators provide suggestions for proactive improvements? | |

| 10. Does each meeting include well-defined ID & A? |

Comments or Questions?

We welcome your comments and questions. Contact us at: [email protected].