In the automotive industry, OEMs rely heavily on a carefully vetted supply chain of tiered suppliers to provide critical components on time and within spec. Whether you are a Tier 3 supplier processing raw materials, a Tier 2 supplier producing a myriad of individual components, or a Tier 1 supplier providing finished goods or sub-assemblies directly to the OEM themselves, it is critical you fulfill your role seamlessly to remain a preferred supplier.

In an industry with tight margins and a low tolerance for delays, it should come as no surprise that Vorne has been invited to speak at numerous events as OEE experts in the automotive industry. Further, Vorne XL is a required tool and manufacturing aid with which to ensure full visibility and OTD in many automotive factories.

Other benefits of XL that customers love include no software to install, no servers to maintain, no recurring fees, and no contracts. Instead you get unlimited users, free technical support, a 3-year warranty, and free software updates. All in an inexpensive, off-the-shelf product.

Driving Improvement for Automotive

Our automotive customers strive to make something more reliable, precise, or cost effective than other options on the market. It is critical to be able to optimize the process while maintaining the product that your customers need.

The Vorne XL Productivity Appliance empowers automotive manufacturers to monitor their processes, improve throughput, and maximize efficiency, all while preserving the integrity of their products. XL drops onto your existing process, making it a quick and easy solution that requires little to no changes on the line.

Key Benefits for Automotive

Our automotive customers produce specialized components and subsystems using a wide variety of processes such as machining and stamping, roll formers, welders and cutters, CNC machines, wire and cable extruders, robotic assembly lines, manual or semi-automated sub assembly and kitting operations, etc. Regardless of the process, they must uphold stringent levels of quality and maintain tight margins to remain profitable, all while navigating the pressure of contracted pricing and deadlines from their customers.

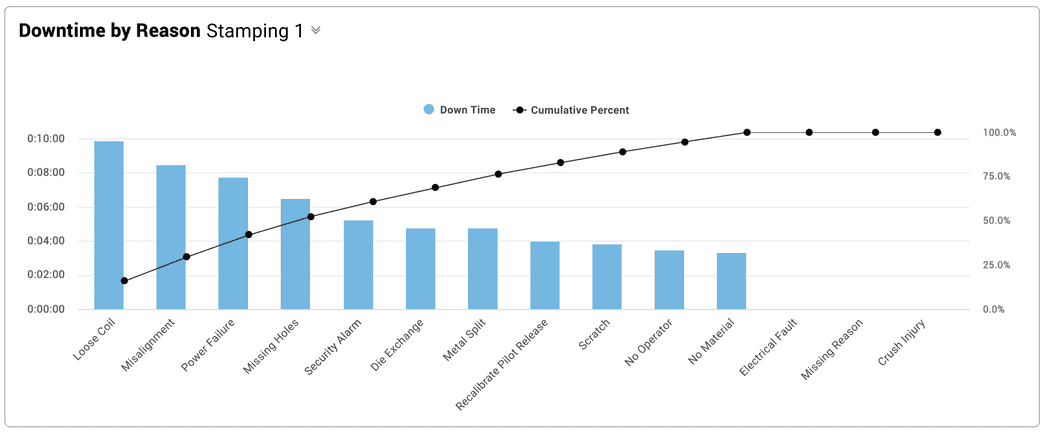

Our XL users greatly rely on and appreciate the robust suite of reporting tools in Vorne XL, benefitting from the ability to:

- 1Improve Changeover Times Drive changeover efficiency by using target times, implementing SMED, or enforcing SIC.

- 2Receive Real-Time Quality Alerts Promote Jidoka or “stop and fix” processes in order to maintain 6S and DPMO standards. Let informed decisions stop production when necessary to limit waste in the form of scrap and non-conforming product.

- 3Analyze Part- and Job-Related Info Feed recorded information such as production totals and labor efficiencies back into your ERP.

- 4View Line Speed and Rates Instantly Use precise performance loss and cycle time information to quickly diagnose and resolve issues.

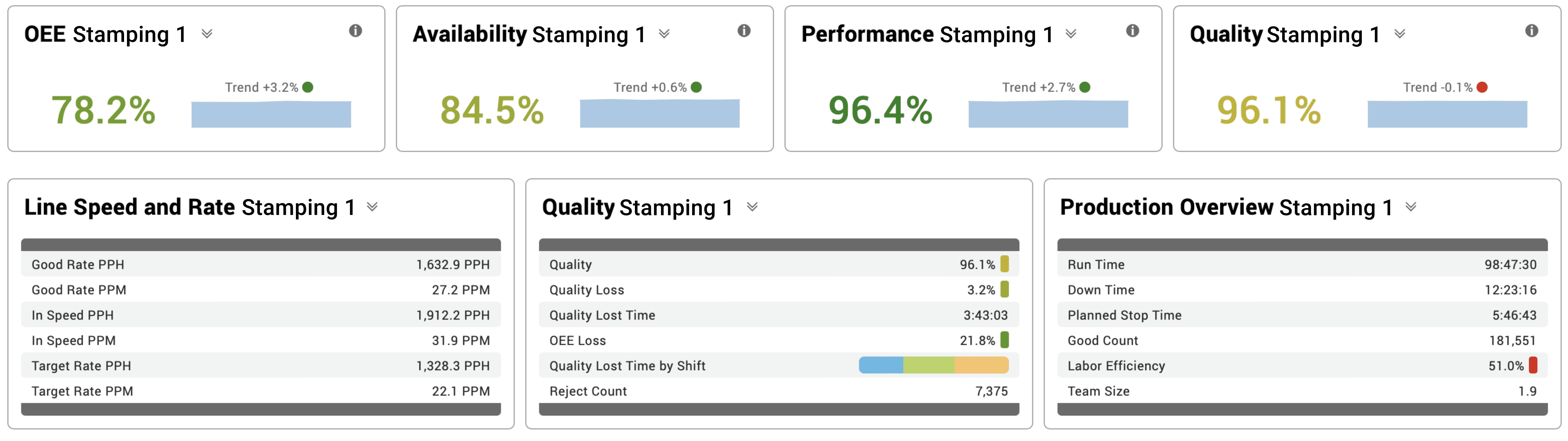

- 5Access Full OEE Metrics Collect and analyze Availability, Performance, and Quality, as required by many automotive manufacturers. Dive even deeper with Six Big Losses and TEEP.

You're in Excellent Company

Vorne XL customers span across 45+ countries and are in virtually every industry - including many in automotive. Take a look at a sampling of automotive manufacturers that have unlocked the benefits of XL to obtain accurate and actionable data, critical insights, and a foundation for their continuous improvement programs.

Learn More About Vorne XL

We would be happy to show you XL, deep dive into your challenges and your processes, and answer any questions you may have. We also offer free 90-day trials. In fact, we have completed thousands of successful XL trials. Did you know that 91.9% of companies that try XL buy XL?

Metrics, Dimensions, and Dashboards

Vorne XL delivers an incredible data foundation and the tools you need to effectively drive your continuous improvement, lean manufacturing, and digital transformation initiatives. With XL you get immediate access to over 100 highly accurate and actionable metrics and 20 data dimensions - in real time and for deep retrospective analysis through historical reporting. There are dozens of built-in reports, and you can easily create your own reporting dashboards.

Vorne XL User Success Stories

XL helps manufacturers in almost every industry improve their process productivity. You will love our free support, free software updates, 3-year warranty, transparent pricing, fast implementation, and of course, the wealth of product features. That is why we have so many customers that share their success stories.

Automotive Specialties

Our XL Productivity Appliance, with its fully integrated OEE reporting system, works well across an extremely broad range of automotive industry specialties including Tier 1, Tier 2, and Tier 3 suppliers. Here are some of the more common specialty areas where XL is used:

- Automotive Assembly Plants

- Automotive Battery Manufacturers

- Automotive Brake System Suppliers

- Automotive Electronics Manufacturers

- Automotive Engine Manufacturers

- Automotive Exhaust System Suppliers

- Automotive Glass Manufacturers

- Automotive Interior Trim Suppliers

- Automotive Lighting Manufacturers

- Automotive Paint Shops

- Automotive Parts Manufacturers

- Automotive Seating Manufacturers

- Automotive Stamping and Fabrication Plants

- Automotive Transmission Manufacturers