Reduce Changeover Times

What Are Changeovers in Manufacturing?

Every manufacturing process has periods of time where equipment is unavailable due to tooling changes, material changes, part changes, program changes, or any other changes to production that must be performed while equipment is stopped. Collectively, these events are referred to as “changeovers”, or alternately as “setup”, “make ready” or “planned down time”.

How Do I Measure Changeover Time?

In order to measure changeover time accurately, it is important to create a clearly defined standard and then consistently apply that standard (over time and across equipment).

What is Changeover Time?

For changeover time, we recommend the following definition:

Changeover time is measured from the last good part of the current part run to the first good part of the next part run.

Benefits of Reducing Changeover Time on Manufacturing Productivity

Reducing changeover time unlocks more productive (value-added) time for running production. Another benefit is that by reducing changeover time you can reduce production batch sizes, work-in-process (WIP), and inventory. Often times, sales teams are able to reduce quoted lead times on products and improve customer satisfaction.

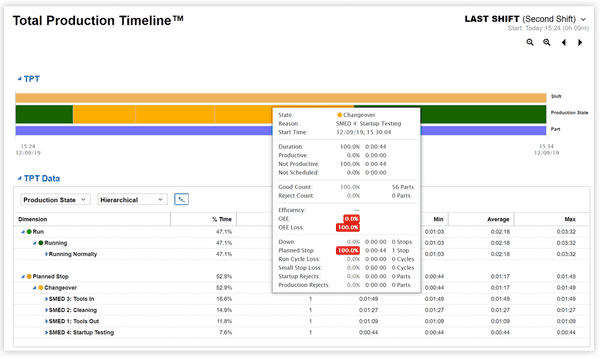

From the perspective of Overall Equipment Effectiveness (OEE) and Total Equipment Effectiveness (TEEP), changeover time is captured as an Availability Loss. From the perspective of the Six Big Losses, changeover time is captured as a Planned Stop.

SMED as a Best Practice for Reducing Changeover Time

Far and away the most commonly accepted best practice for reducing changeover time is Single-Minute Exchange of Die (SMED). Single-minute refers to reducing changeover times to less than 10 minutes, and exchange of dies refers back to initial historic work performed by Shigeo Shingo developing SMED and applying it to automotive presses. In fact, Shigeo Shingo was able to reduce changeover times by a factor of 20 or more across a wide range of companies.

In SMED, the changeover process is broken into a sequenced list of steps called elements. The objective of SMED is to remove as many elements from the changeover process as possible by separating or converting them (moving them external to the changeover) and then streamlining any remaining elements (completing them faster, easier, or in parallel with other elements).

How to Reduce Changeover Time

Three highly effective strategies for reducing changeover times are:

- Implement Single-Minute Exchange of Die (SMED)

- Make Changeover Time Visual

- Provide Advance Notification of Changeovers

Implement SMED for Quick Changeovers

Problem: We want to significantly reduce our changeover times.

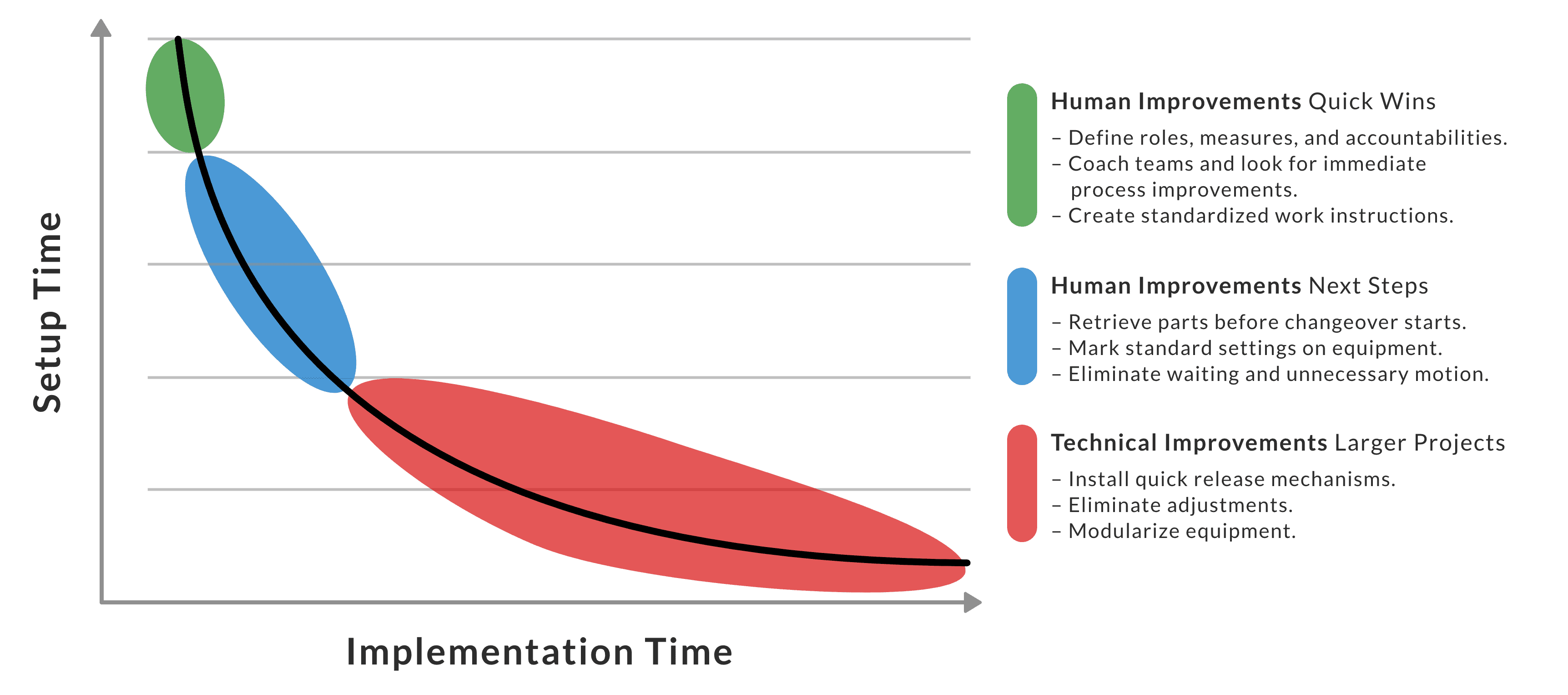

Strategy: Apply SMED to achieve dramatic reductions in changeover time. SMED for quick changeovers splits the changeover process into a sequenced list of steps called elements. The essence of SMED is to transform as many elements as possible to “external” (performed while the equipment is running), and to remove or streamline the remaining elements. SMED projects have three conceptual stages:

- Separate: Move elements to external.

- Convert: Modify elements so they can be external, or remove them completely.

- Streamline: Complete elements faster.

Although applying SMED at an expert level can be complex and time consuming, there are almost always opportunities for quick wins. Especially, since SMED works very well in an iterative process. The above process is typically repeated in multiple passes, where a good goal for each pass is to cut the changeover time in half (hence the biggest wins are typically in the first pass).

Solution: XL includes a complete SMED overview as one of its integrated Improvement Techniques. XL can also track changeover elements (see below), and display actual and target time for each element on the XL scoreboard. By reviewing historical reports you can quickly identify which elements of the changeover are meeting targets and which need closer attention.

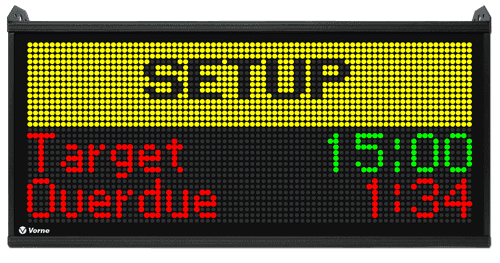

Make Changeover Time Visual With A Scoreboard

Problem: Our operators don't know if they are on pace for any given changeover.

Strategy: Provide real-time plant floor indication for how long changeovers are taking compared to the target time.

Solution: The XL scoreboard displays a target and remaining time for each changeover (a visual factory best practice). For example:

- Display the changeover target time (e.g., 15 minutes)

- Display a count-down of the target time that flashes red when the changeover is over its budgeted time

A variation is to break the changeover into SMED step elements (see above), with a visual timer for each step.

Provide Advanced Notification Of Changeovers

Problem: Our teams are often unprepared for changeovers. We don't always have our tools, materials, and people ready on time.

Strategy: Use job completion information to notify your team to start preparing for a changeover event.

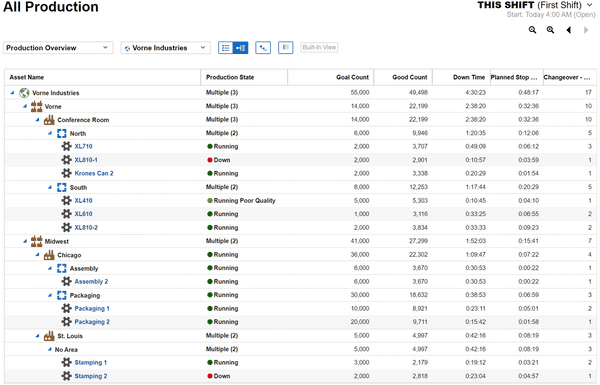

Solution: XL includes job metrics that count down remaining production for the current job. XL tracks Job Goal Count (how many pieces you plan to make), Pieces to Goal (the amount of pieces remaining), and Percent Toward Goal. This information can be displayed on the XL scoreboard and is also available for all production assets through the All Production dashboard (see below).