Packaging Manufacturing

The packaging industry is a 200-billion-dollar+ industry (and growing), which makes it a very attractive market, but also extremely competitive. In an industry where branding and name recognition are absolutely critical to maintaining market share, packaging companies strive to excel in producing high-quality, on-brand packaging while continuing to innovate through new products and methods for their consumers.

With susceptibility to supply chain shortages and pressure to find new, sustainable materials and production practices, it’s easy to understand why so many companies rely on Vorne XL’s automated OEE and production monitoring solutions to maximize efficiencies, reduce costs, and secure their bottom line. Other benefits of XL that our packaging customers love include no software to install, no servers to maintain, no recurring fees, and no contracts. Instead you get unlimited users, free technical support, a 3-year warranty, and free software updates. All in an inexpensive, off-the-shelf product.

Driving Improvement for Packaging

Our packaging customers strive to make something extraordinarily appealing, highly affordable, extremely durable, and every bit as sustainable as other options on the market, so it is critical to be able to optimize the process while maintaining the product that your customers know and love.

The Vorne XL Productivity Appliance empowers packaging manufacturers to monitor their processes, improve throughput, and maximize efficiency, all while preserving the integrity of their products' brand recognition. XL drops onto your existing process, making it a quick and easy solution that requires little to no changes to your manufacturing process.

Key Benefits for the Packaging Industry

The packaging industry utilizes a vast spectrum of manufacturing equipment, including many highly specialized processes. The beauty and simplicity of Vorne XL is that this specialization doesn’t impact how XL works. XL includes I/O to easily integrate with your process, a scoreboard for your operators, and built-in reporting for your managers. It is hands-down the simplest solution for scaling from machine to enterprise. Whether you are running blow molders, injection molders, die cutters, sheet-fed printers, flexographic printers, folders/gluers, or shrink-sleeve applicators, you only need one solution. Vorne XL delivers and enables:

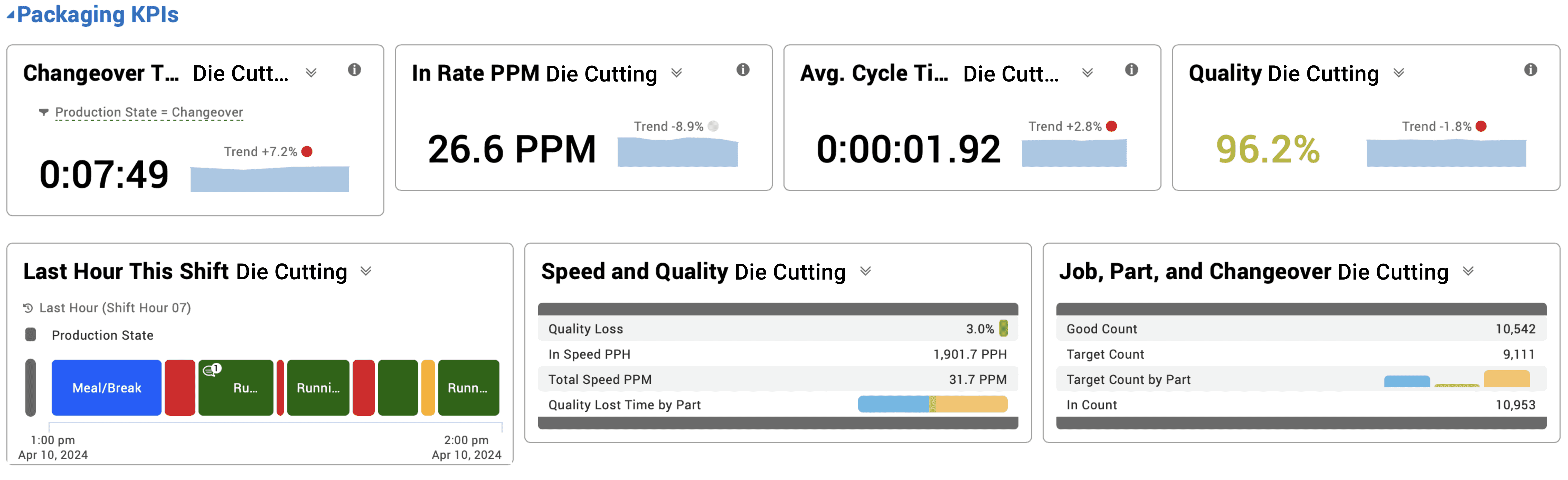

- 1Accurate Run Rates Allow data, not opinions, to drive decisions such as adjusting run rates to achieve the ideal balance of total throughput with respect to quality. Visualize your ideal cycle time against your average run cycle time by SKU for more precise and reliable planning and budgeting.

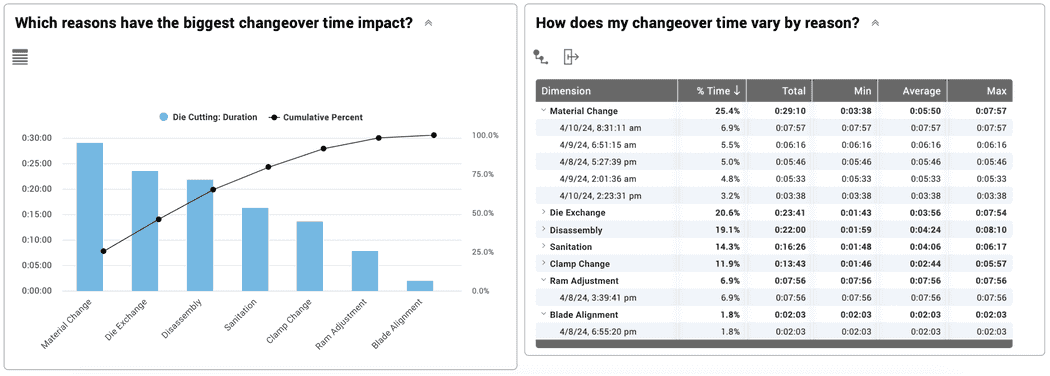

- 2Improved Changeovers Single and multi-die changeovers require varying amounts of time to complete. Often, the key to a consistent product is a consistent changeover process. The ability to easily and accurately compare changeovers times makes it possible to establish and maintain a standard process with minimal variance.

- 3Real-Time Problem Identification and Escalation Identify, assess, and react instantly based on real-time data and alerts sent to the appropriate individuals. End the continuous cycle of expediting customer orders by understanding precisely when jobs will finish based on accurate run rates and downtime visibility. Dramatically improve your ability to meet deadlines.

- 4Around-the-Clock Data Collection Many manufacturers struggle with performance on alternate shifts. Access to real-time and historical data makes it easy to visualize trends and compare shifts side-by-side to quickly understand what occurred and select the appropriate corrective actions. Clear visibility, available even when you aren’t on the plant floor, provides the comfort and security you need to ensure your lines are running optimally.

- 5Adaptive Targets and Goals Tied to SKUs It is common to have significant variation in the speed at which individual SKUs run, even on a single production line. This is why the ability to set takt times or goal counts by SKU is critical to driving operational efficiency with your operators on the plant floor. Displaying accurate, clear, and achievable targets by product is essential to winning the shift.

You're In Excellent Company

Vorne XL customers span across 45+ countries and are in virtually every industry - including many in packaging. Take a look at a sampling of packaging manufacturers that have unlocked the benefits of XL to obtain accurate and actionable data, critical insights, and a foundation for their continuous improvement programs.

Learn More About Vorne XL

We would be happy to show you XL, deep dive into your challenges and your processes, and answer any questions you may have. We also offer free 90-day trials. In fact, we have completed thousands of successful XL trials. Did you know that 92.8% of companies that try XL buy XL?

Metrics, Dimensions, and Dashboards

Vorne XL delivers an incredible data foundation and the tools you need to effectively drive your continuous improvement, lean manufacturing, and digital transformation initiatives. With XL you get immediate access to over 100 highly accurate and actionable metrics and 20 data dimensions - in real time and for deep retrospective analysis through historical reporting. There are dozens of built-in reports and you can easily create your own reporting dashboards.

Vorne XL Customer Success Stories

XL helps manufacturers in almost every industry improve their process productivity. You will love our free support, free software updates, 3-year warranty, transparent pricing, fast implementation, and of course, the wealth of product features. That is why we have so many customers that share their success stories.

Packaging Specialties

Our XL Productivity Appliance, with its fully integrated OEE reporting system, works well across an extremely broad range of packaging industry specialties. Here are some of the more common specialty areas where XL is used:

- Aerosol Packaging

- Automated Packaging Equipment

- Bag Sealing

- Blister Packaging

- Blow Molding

- Bottle Filling

- Box Making, Folding, Gluing, Sealing, & Taping

- Can Seaming

- Canning and Bottling

- Carton Erecting, Packing, Sealing, & Closing

- Case Packing

- Complex Packaging Processes

- Flexible Packaging Systems

- Injection Molding

- Inspection and Quality Control

- Palletizing and Depalletizing

- Rigid Packaging

- Strapping and Banding