Metal Forming and Fabrication

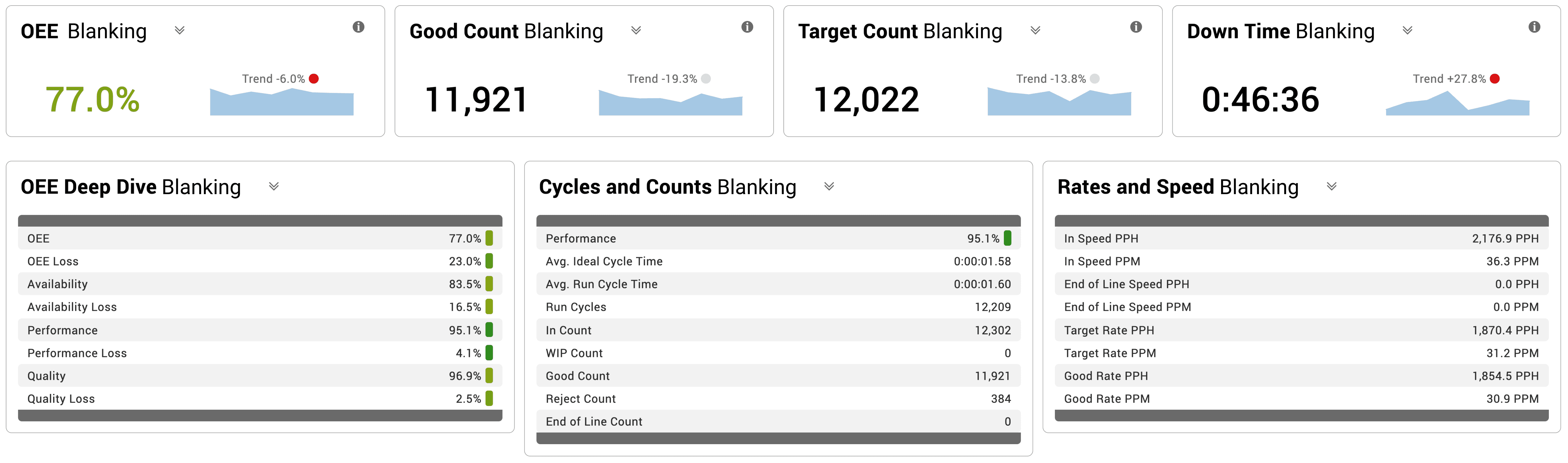

Forming and fabricating metal parts requires a unique combination of force and precision. Whether you are roll forming, slitting, or even welding and cutting, it takes a significant amount of capital investment to operate in this industry. To maintain profitability, metal formers and fabricators must keep a keen eye on cycle times, changeovers, downtime, and quality… all the elements of OEE (Overall Equipment Effectiveness). That is why OEE is considered essential to the industry.

Metal manufacturers rely on automated production monitoring systems like Vorne XL to provide visibility into their process so they can intervene when necessary. Historical production data and trends on over 100 metrics and 20+ data dimensions, real-time data displayed on the plant floor, and automated alerts and push notifications will transform your improvement actions from reactive to proactive.

Other benefits of XL that customers love include no software to install, no servers to maintain, no recurring fees, and no contracts. Instead you get unlimited users, free technical support, a 3-year warranty, and free software updates. All in an inexpensive, off-the-shelf product.

Driving Improvement for Metal Forming and Fabrication

Our metal forming and fabrication customers strive to make parts within tight tolerances and with minimal scrap, as cost-effectively as possible. It is critical to be able to optimize the process while maintaining the product quality and delivery timelines that their customers require.

The Vorne XL Productivity Appliance enables metal forming and fabrication manufacturers to monitor their processes in real time, improve throughput, and maximize efficiency, all while preserving the integrity of their products and manufacturing process. XL drops onto your existing process, making it a quick and easy solution that requires little to no changes on the line. This is a unique and critical advantage of Vorne XL.

Key Benefits for Metal Forming and Fabrication Manufacturers

Vorne XL is completely agnostic to the type of equipment in your manufacturing process. This is a huge advantage as you can easily apply XL to any process and get the same deep wealth of information. XL includes I/O to integrate with your process, a scoreboard for your operators, and built-in reporting for your managers. Even better, it easily and incrementally scales from machine to enterprise.

Monitor your roll formers, slitters, CNC’s, fine blanking machines, robotic lasers and cutters, press brakes, and other equipment with one solution, quickly seeing benefits such as:

- 1Real-Time Production Rates See real-time run rates and line speeds. Cumulate and trend highly accurate cycle time data over time to understand the impact cycle loss has on your margins.

- 2Automated Email Alerts Metal forming and fabrication equipment tends to be bulky and loud. Ensure the right people are receiving critical line status updates by sending alerts to their phone or email, drawing attention to where it is most needed.

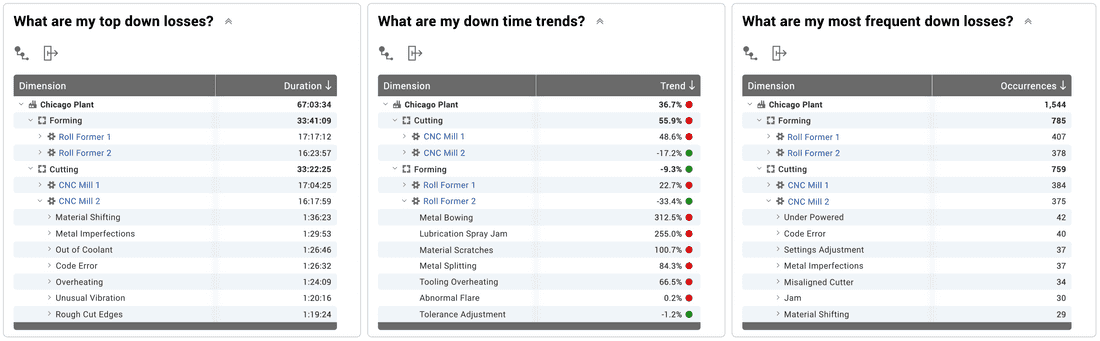

- 3Downtime Pareto Equipment downtime keeps plant managers up at night. The ability to accurately identify and quantify loss by specific reasons and assets enables manufacturers to attack the true source of loss and mitigate it moving forward.

- 4Part Level Data An increase in customer demand may dictate either longer production runs or repeated shorter runs with fast changeovers. Analyze OEE, Six Big Losses, and related TPM metrics to assess which part runs best on which line, changeover effectiveness, and labor efficiency, finding your sweet spot for production efficiency, inventory turns, and profitability.

- 5Industrial Plant Floor Display An integrated plant floor scoreboard with vibrant, clear, and precise KPIs ensures your operators are aligned with planning and management. Promote ownership of the line and foster communication between teams in order to minimize downtime and “win” the shift.

You're In Excellent Company

Vorne XL customers span across 45+ countries and are in virtually every industry - including many in metal forming and fabrication. Take a look at a sampling of metal forming and fabrication manufacturers that have unlocked the benefits of XL to obtain accurate and actionable data, critical insights, and a foundation for their continuous improvement programs.

Learn More About Vorne XL

We would be happy to show you XL, deep dive into your challenges and your processes, and answer any questions you may have. We also offer free 90-day trials. In fact, we have completed thousands of successful XL trials. Did you know that 92.8% of companies that try XL buy XL?

Metrics, Dimensions, and Dashboards

Vorne XL provides you with an incredible data foundation and an outstanding suite of reporting tools to effectively drive your continuous improvement, lean manufacturing, and digital transformation initiatives. With XL you get immediate access to over 100 highly accurate and actionable metrics and 20 data dimensions - in real time and for deep retrospective analysis through historical reporting. There are dozens of built-in reports, and you can easily create your own reporting dashboards.

Vorne XL User Success Stories

XL helps manufacturers in almost every industry improve their process productivity. You will love our free support, free software updates, 3-year warranty, transparent pricing, fast implementation, and of course, the wealth of product features. That is why we have so many customers that share their success stories.

Metal Forming and Fabrication Specialties

Our XL Productivity Appliance, with its fully integrated OEE reporting system, works well across an extremely broad range of metal forming and fabrication industry specialties. Here are some of the more common specialty areas where XL is used:

- 3D Printing

- Additive Manufacturing

- Coil Processing

- Cutting and Shearing

- Die Casting

- Extrusion

- Forging

- Heat Treatment

- Laser Cutting

- Metal Bending and Forming

- Metal Cutting, Punching, and Welding

- Metal Grinding and Polishing

- Metal Rolling and Spinning

- Metal Surface Finishing

- Plasma Arc Welding and Cutting

- Roll Forming

- Sheet Metal Stamping

- Shot Blasting

- Tube Bending

- Waterjet Cutting