Electronics Manufacturing

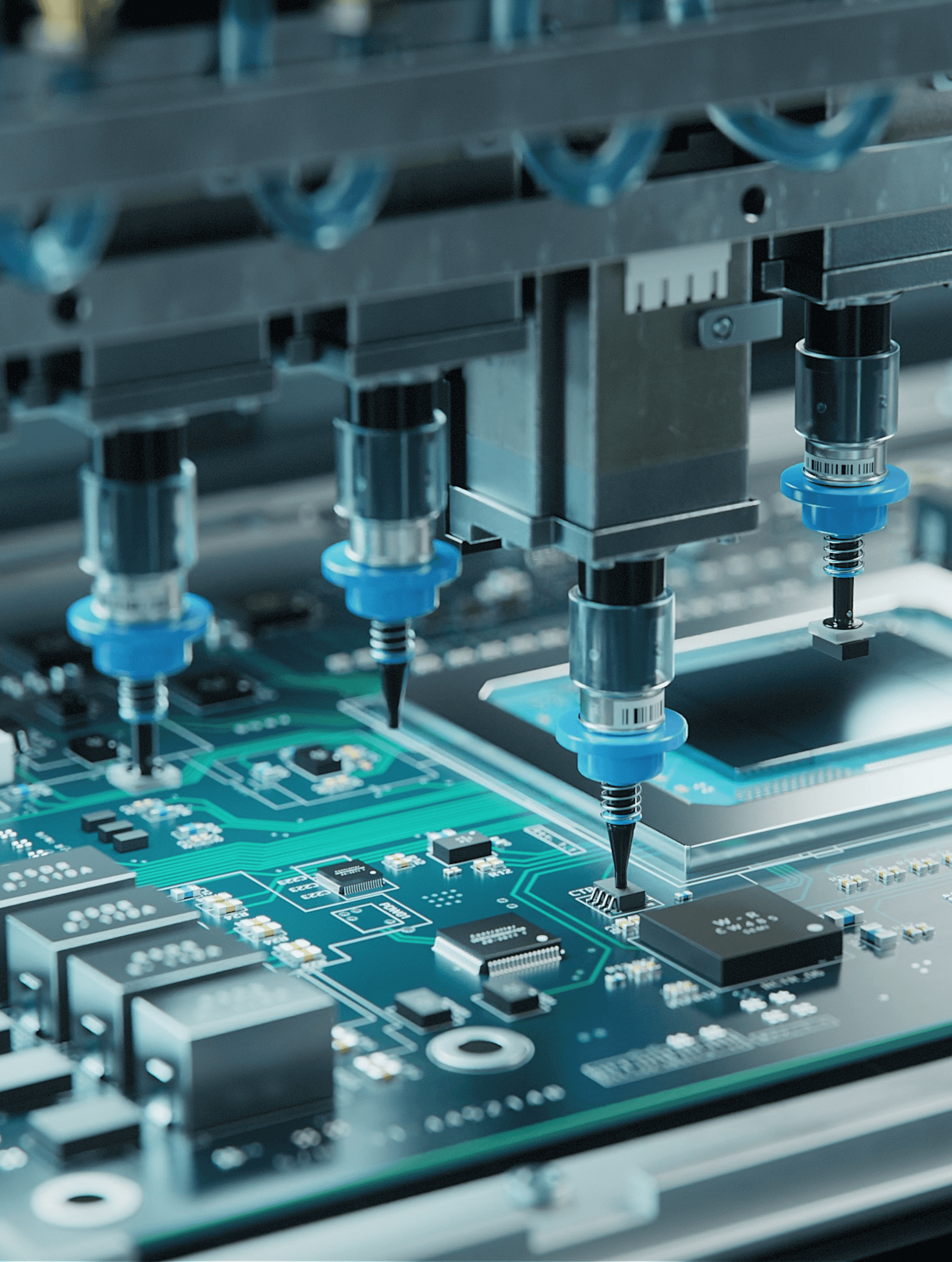

Electronic Manufacturing Services (EMS) provide essential electronic components and subassemblies to a broad range of markets including automotive, aerospace, defense, healthcare, industrial, telecom, and consumer electronics. Whether producing small quantities of mission-critical, highly precise electronic components or large quantities of mass market circuit assemblies, EMS providers can greatly benefit from real-time production data, visualization of equipment status across every work center on their plant floor, and historical analytics for thorough retrospective analysis.

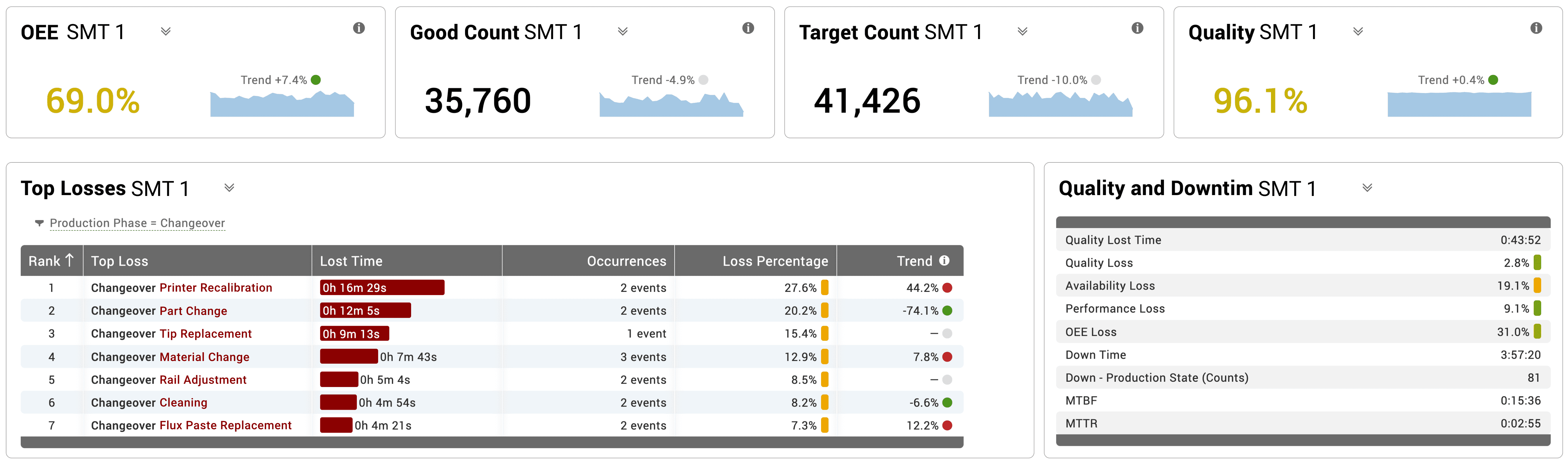

With constant pressure to reduce manufacturing and operating costs while consistently delivering products built to stringent quality standards and within tight timelines, EMS providers rely on automated production monitoring solutions to expose all lost production time, typically within a framework of OEE (Overall Equipment Effectiveness). Vorne XL provides a simple, powerful, and comprehensive solution that moves electronics manufacturing operations far beyond manual data capture to gain critical insights for effectively driving process improvement and actualizing change with 100+ metrics and 20+ data dimensions.

Other benefits of XL that customers love include no software to install, no servers to maintain, no recurring fees, and no contracts. Instead you get unlimited users, free technical support, a 3-year warranty, and free software updates. All in an inexpensive, off-the-shelf product.

Driving Improvement for Electronics Manufacturing

Our electronics manufacturing customers are typically seeking a solution that enables them to optimize their processes while maintaining the precision and product quality that their customers require.

The Vorne XL Productivity Appliance enables electronics manufacturers to monitor their processes in real time, improve throughput, and maximize efficiency, all while preserving the integrity of their products and manufacturing process. XL drops onto your existing process, making it a quick and easy solution that requires little to no changes on the line. This is a unique and critical advantage of Vorne XL.

Key Benefits for Electronics Manufacturers

Vorne XL is completely agnostic to the type of equipment in your manufacturing process. This is a huge advantage as you can easily apply XL to any process and get the same deep wealth of information. XL includes I/O to integrate with your process, a scoreboard for your operators, and built-in reporting for your managers. Even better, it easily and incrementally scales from machine to enterprise.

Monitor your SMT lines, pick and place, wave solder, select solder, conformal coating, potting, ICT beds or semi-automated assembly lines, and other equipment with one solution, quickly seeing benefits such as:

- 1Real-Time Machine Monitoring Planners rely on up-to-date job statuses to schedule work orders for specific equipment. XL includes real-time dashboards that provide live production counts, goals, and progress towards completion, providing clarity on what’s running where and whether it’s on track to finish as scheduled.

- 2Changeover Targets and Notifications Efficient line changeovers require the coordination of multiple teams to effectively pull the right kits while setting up the proper profiles on the line. Set changeover targets for your operators and send email or text notifications to the stock room when it’s time to allocate material.

- 3Flexibility of Digital Inputs EMS shops often have a mix of both state-of-the-art and legacy equipment. Whether your equipment has the latest PLC or no integrations at all, XL enables quick and simple integration by connecting through virtually any 5-24 VDC digital input.

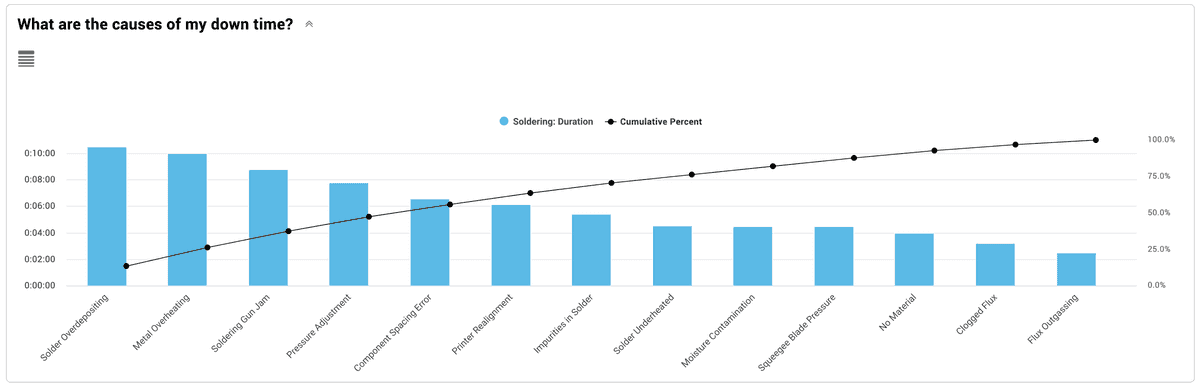

- 4Downtime Pareto Poka-yoke, or error proofing, is very common in the EMS industry as a method to reduce downtime and quality loss. View historical downtime by reason or quality loss by reason and part to create a culture of learning and reduce loss moving forward.

- 5Easy Integration Whether you leverage our API or turnkey integration solutions, easily set up communication between Vorne XL and your ERP or MES system to pull production standards and goals, or even update production numbers for the latest job.

You're In Excellent Company

Vorne XL customers span across 45+ countries and are in virtually every industry - including many in electronics manufacturing. Take a look at a sampling of electronics manufacturers that have unlocked the benefits of XL to obtain accurate and actionable data, critical insights, and a foundation for their continuous improvement programs.

Learn More About Vorne XL

We would be happy to show you XL, deep dive into your challenges and your processes, and answer any questions you may have. We also offer free 90-day trials. In fact, we have completed thousands of successful XL trials. Did you know that 92.8% of companies that try XL buy XL?

Metrics, Dimensions, and Dashboards

Vorne XL provides you with an incredible data foundation and an outstanding suite of reporting tools to effectively drive your continuous improvement, lean manufacturing, and digital transformation initiatives. With XL you get immediate access to over 100 highly accurate and actionable metrics and 20 data dimensions - in real time and for deep retrospective analysis through historical reporting. There are dozens of built-in reports, and you can easily create your own reporting dashboards.

Vorne XL User Success Stories

XL helps manufacturers in almost every industry improve their process productivity. You will love our free support, free software updates, 3-year warranty, transparent pricing, fast implementation, and of course, the wealth of product features. That is why we have so many customers that share their success stories.

Electronics Specialties

- Automated Assembly

- Automated Test Equipment (ATE)

- Circuit Board Assembly

- Component Placement

- Die Bonding and Wire Bonding

- Electronic Component Sorting

- Electronics Cleaning

- Electronics Coating and Encapsulation

- Electronics Inspection

- Electronics Packaging

- Electronics Soldering

- PCB Drilling and Routing

- PCB Etching and Plating

- PCB Printing and Imaging

- Semiconductor Fabrication

- Semiconductor Test

- Surface Mount Technology (SMT)

- Through-Hole Assembly