Total Effective Equipment Performance (TEEP)

What Is Total Effective Equipment Performance (TEEP)?

TEEP (Total Effective Equipment Performance) is a metric that helps manufacturers find the most cost-effective ways to increase production. In the context of their relationship to OEE, TEEP and related metrics like utilization can also help answer common questions in manufacturing, such as:

- “Is a break considered downtime?”

- “Should I invest in more capital equipment or schedule additional overtime shifts?“

Because TEEP takes unscheduled time into consideration, it can also help determine:

- Whether you can better leverage your current equipment across all available time, or

- Whether it’s time to add or upgrade your existing equipment.

Read on to learn how TEEP can help your company better understand your manufacturing time usage!

How Does TEEP Differ from OEE?

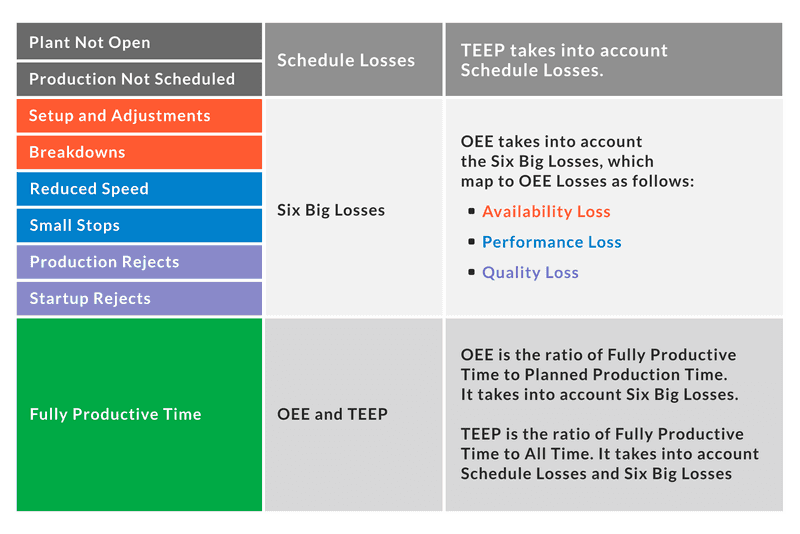

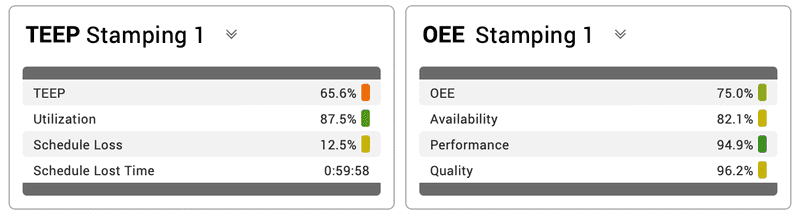

OEE focuses on losses during planned production time and is calculated as Availability * Performance * Quality. TEEP adds Utilization to that equation (A * P * Q * U), shifting the focus to how you can increase throughput by taking advantage of unscheduled time using your existing equipment. To break it down simply:

- OEE focuses on planned production time (run time, downtime, planned stop time such as changeovers, etc). It answers the question, “When we are scheduled to run, are we running well?“

- TEEP focuses on all time, including time when production is not scheduled (breaks/lunches, no shift, meetings, shift handoffs, etc). It answers the question, “How much of all time is fully productive?” It is sometimes referred to as exposing your “hidden factory.”

It is important to note that because breaks are periods of time during which the line is not scheduled to run, breaks are not considered downtime. Therefore, they are not an availability loss or a component of OEE; rather, they are a scheduling loss and a component of TEEP.

Now that the differences between OEE and TEEP are clear, let’s delve into how you can use them to make decisions regarding manufacturing productivity.

How Can I Leverage My Current Equipment within the Shift?

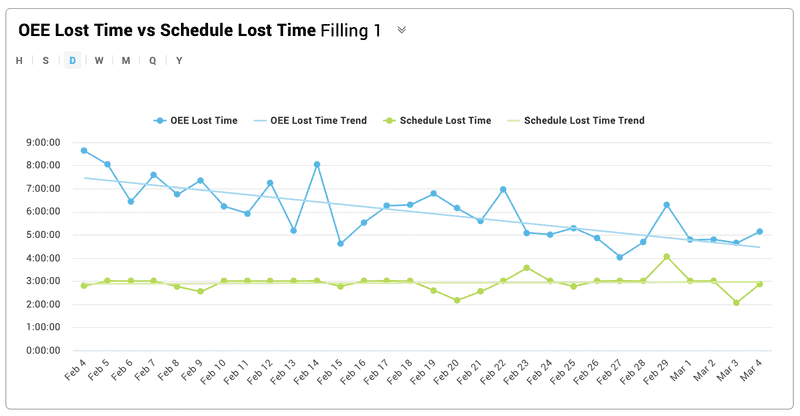

TEEP and OEE both reveal whether you are giving up opportunities to produce more within the shift (schedule loss and OEE loss, respectively).

Resist the temptation to expand your capacity by adding overtime, shifts, or equipment before developing a complete understanding of your current losses within the shift. Adding resources first could mean you are just exacerbating a problem - basically, replicating the same poor practices on additional equipment.

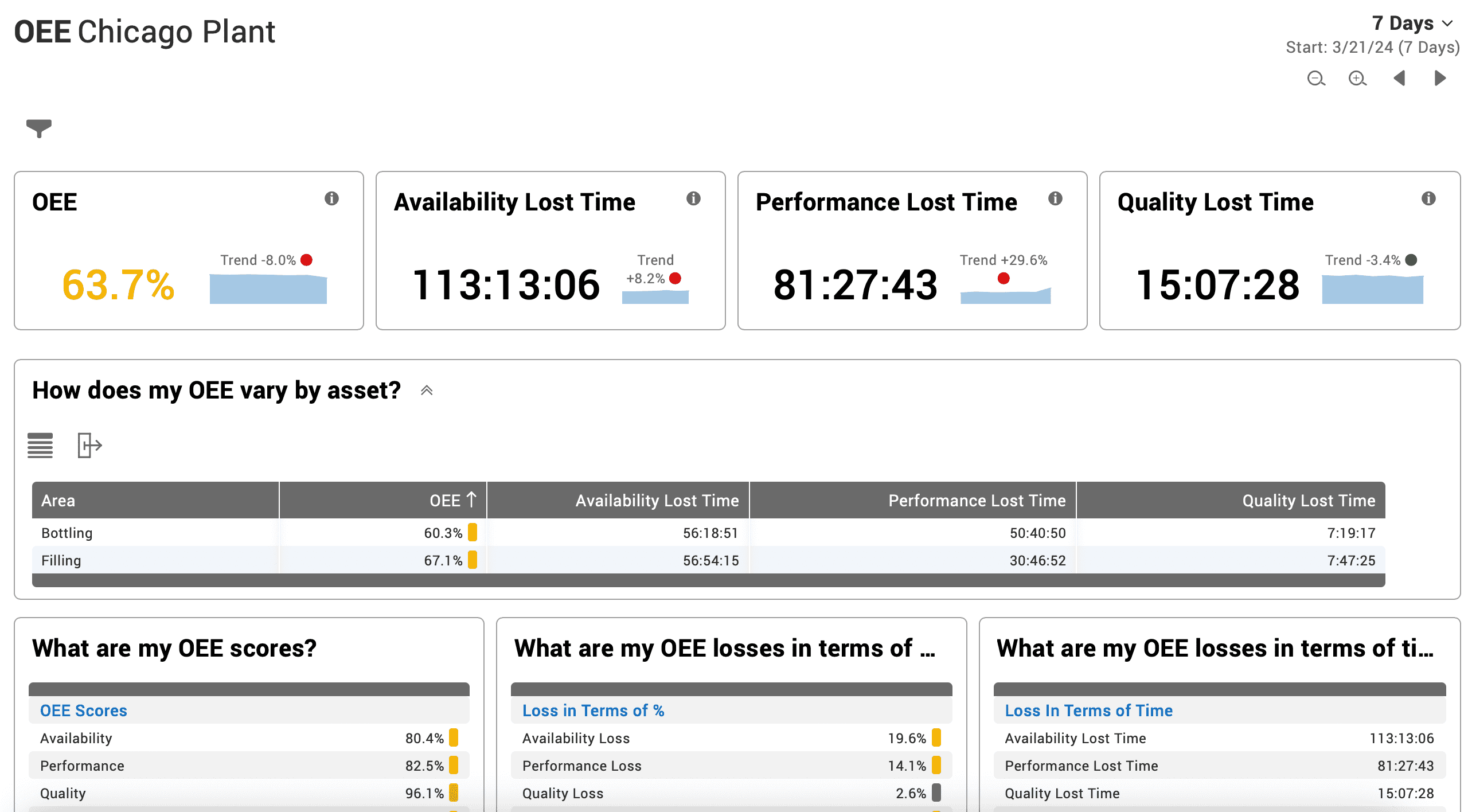

It is essential to accurately measure all three OEE losses (or even better, the Six Big Losses). Either way, in order to have accurate and comprehensive loss data, it is important to automate data collection.

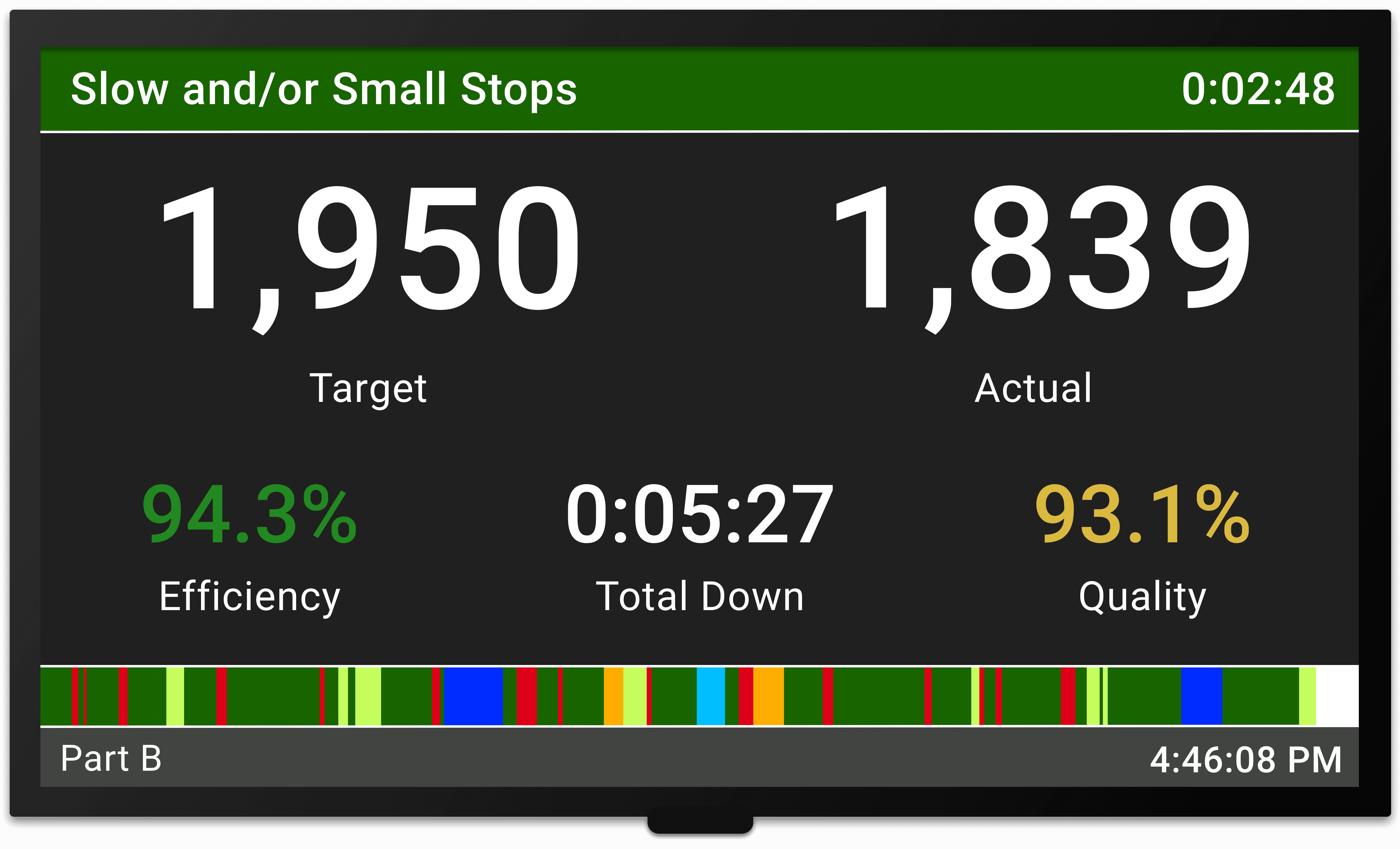

Once equipped with data from a system like Vorne XL, many manufacturers are surprised when the data exposes that their equipment can run faster than they thought possible due to outdated time studies or upgrades to the line over time. Others have found that small stops may be sinking their OEE performance. These types of losses are often hidden below the surface - they are far less obvious than downtime.

If you need to increase production, you can do so in two ways:

- You can focus on OEE by running faster, with fewer stops, or at higher quality.

- Alternatively, you can focus on TEEP by expanding the amount of time you are running within the shift (converting not scheduled time to run time).

Consider your team’s strengths to decide where you have the most potential for improvement. For example, would it be easier for your team to meet excess demand by reducing changeover times, increasing speed on the line, or staggering operator breaks? Let logic plus data drive your decisions.

Schedule lost time is often overlooked. It reveals additional potential production time. For example:

- Time dedicated to breaks and lunches during which you can overlap or stagger operator schedules to keep lines running

- Startup meetings that can be refocused and condensed (e.g., 15 minutes to 10 minutes)

- Stops between shifts that can be converted to seamless shift handoffs

- Equipment warm-up time at the start of the first shift that can be eliminated if one team member arrives early to prepare the line

How Can I Leverage My Current Equipment outside of the Shift?

Once you assess your options for expanding production within the shift, you may decide to look outside of the shift for ways to increase your capacity. Leveraging your existing equipment outside of the shift leaves the realm of OEE and enters firmly into the realm of TEEP.

We recommend analyzing utilization, which is calculated by dividing planned production time by all time. Utilization shows what percentage of time is used for production. If you are running two eight hour shifts five days per week, your utilization is capped at 48%. In reality, it would probably be even lower unless you are overlapping operator schedules because breaks cut into planned production time and reduce utilization.

You can use utilization as a tool to help you choose between your options for producing more. For example, if you are struggling to meet production goals and end up having a line regularly scheduled to run overtime, you can analyze the cost of this compared to staffing an additional shift.

Do I Need to Purchase New Equipment?

If you still can’t reach your production goals by optimizing production within and outside of the shift, it may be time to consider purchasing new equipment. However, we caution you to ensure you are collecting accurate and comprehensive data before making that decision.

We have seen situations where teams incorrectly assumed their equipment was set to an ideal balance between run rate and quality loss, so to meet demand, they invested in new equipment. Later, when they started collecting accurate and comprehensive cycle time and quality loss data, they realized that a much better solution was right in front of them - capitalizing on the underutilized speed of the machines that they already had. Companies usually have a decent (albeit not entirely accurate) sense of downtime and quality loss, but they rarely fully understand the implications of performance loss and often don’t fully analyze schedule loss.

One last quick tip. Much of the same “hidden” information, especially OEE Performance metrics such as slow cycles and small stops, is invaluable when specifying and validating new equipment.