OEE (Overall Equipment Effectiveness)

What Is OEE in Manufacturing?

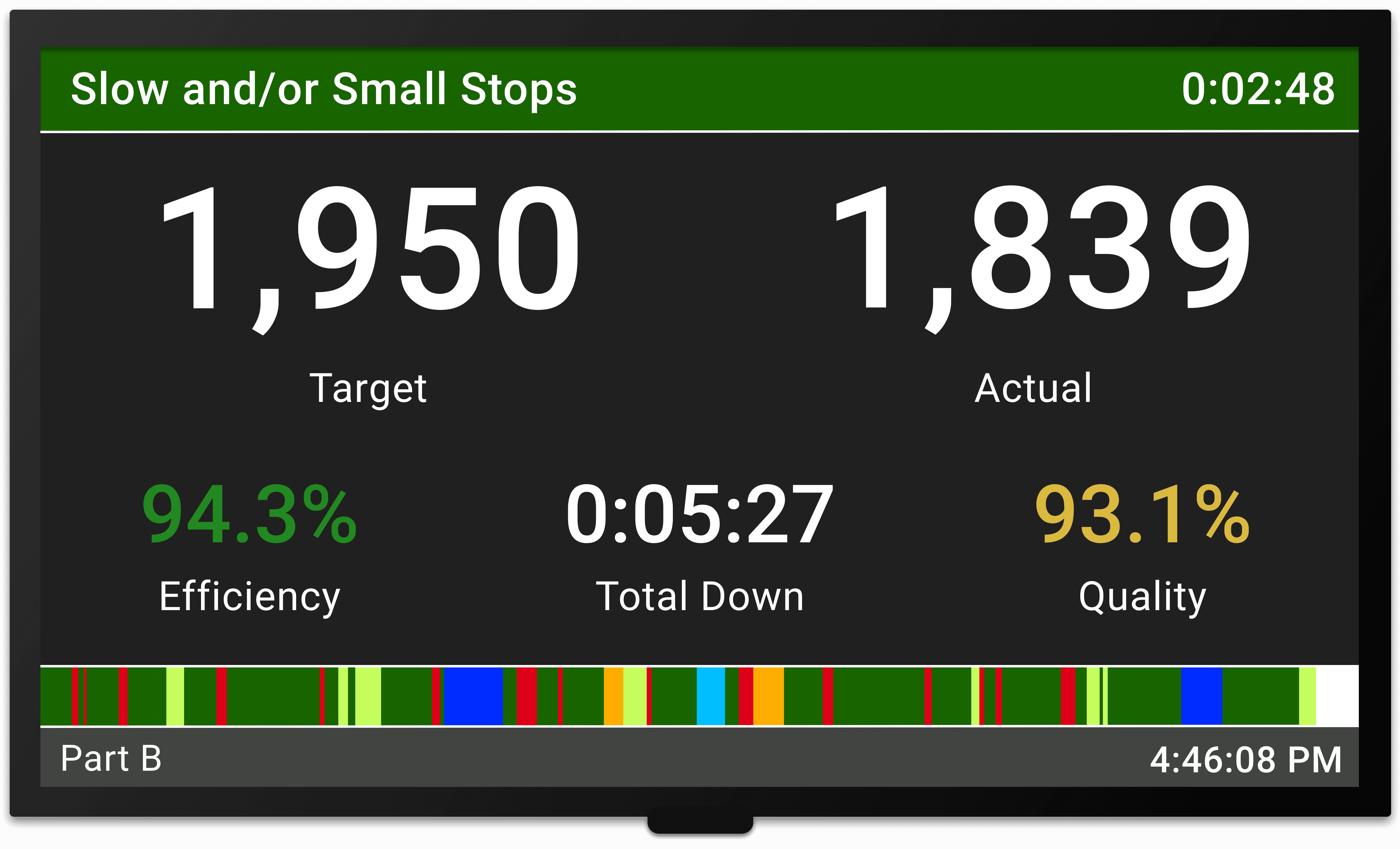

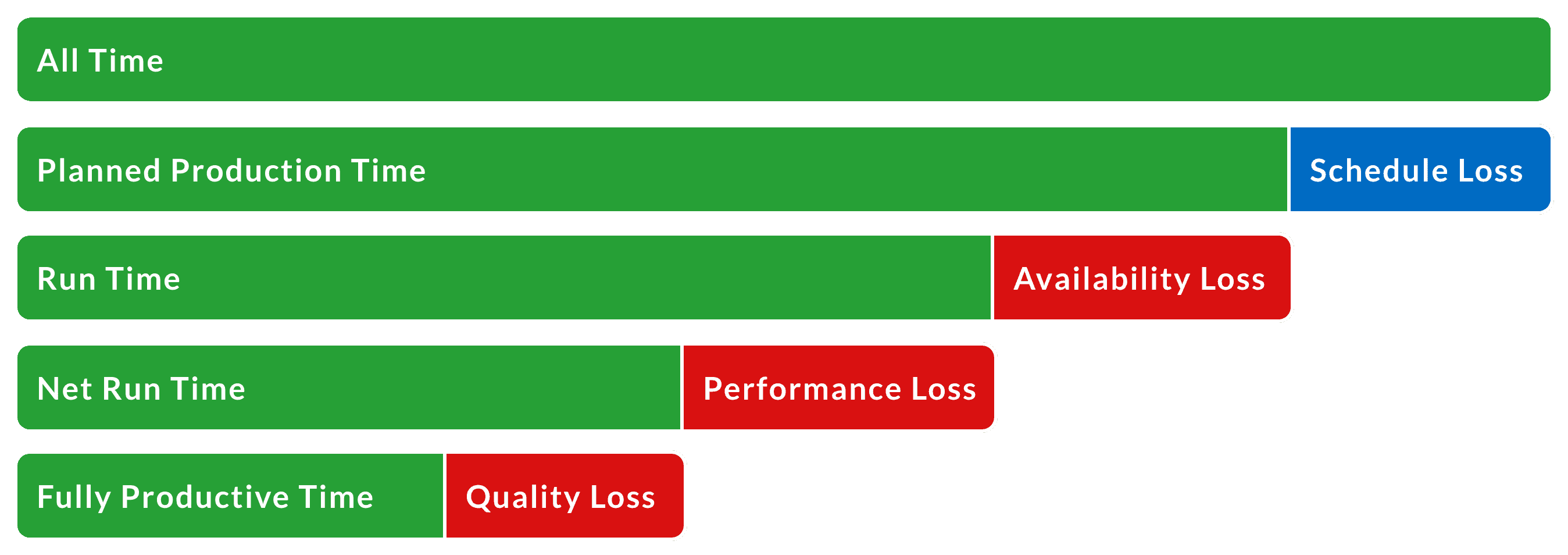

Overall Equipment Effectiveness (OEE) is a metric that identifies the percentage of planned production time that is truly productive. OEE is the gold-standard for measuring lost productive time in manufacturing. OEE is calculated from three underlying factors: Availability, Performance, and Quality. Each of these factors represents a different perspective of how close your manufacturing process is to perfect production.

| OEE Factor | Perfect Production |

|---|---|

| Availability | An Availability score of 100% means the process is always running during planned production time (it's never down). |

| Performance | A Performance score of 100% means when the process is running it is running as fast as possible (at the theoretical maximum speed; each part at the Ideal Cycle Time). |

| Quality | A Quality score of 100% means there are no defects (only good parts are produced). |

What is Perfect Production?

Perfect production is an OEE score of 100%, which means you are manufacturing only good parts, as fast as possible, with no downtime.

The Three OEE Factors and Loss

Another way to look at the three factors is in terms of loss:

- Availability Loss includes all events that stop planned production for an appreciable amount of time (usually several minutes). Examples include equipment failures, unplanned maintenance, material shortages, and changeovers.

- Performance Loss includes all factors that cause the process to operate at less than the maximum possible speed when running (including both slow cycles and small stops). Examples include machine wear, substandard materials, and misfeeds.

- Quality Loss includes productivity lost from manufacturing parts that do not meet quality standards after the first pass (similar to the concept of first pass yield). This includes scrap and parts that require rework.

OEE works particularly well for discrete manufacturing processes, where it is used to measure equipment performance.

Breaks and changeovers should be included in Planned Production Time (and thus as part of the OEE calculation). In general, if time can be used for value-added production (i.e., manufacturing to meet customer needs as opposed to manufacturing for inventory), it should be included in OEE. This helps ensure that all losses are tracked and that the true capacity of equipment is exposed.

OEE should be part of a balanced approach to improving productivity. Solely focusing on OEE can encourage teams to overproduce (leading to excess inventory), run equipment beyond rated parameters (potentially leading to safety issues), overstaff processes (reducing labor productivity), or other counterproductive behaviors.

Once a baseline OEE score has been established for a piece of equipment, tracking OEE over time provides an objective measure of how much progress has been made towards improving manufacturing productivity.

Unlocking the power of OEE is all about driving improvement through tools targeted at each type of loss. For example, Top Losses and SMED are very effective for addressing Availability Loss, Short Interval Control is very effective for addressing Performance Loss, and Standardized Work is very effective for addressing Quality Loss.

Benefits of OEE

In the short term, OEE identifies the total opportunity for improvement (sometimes referred to as “uncovering the hidden factory”) for a given piece of equipment (or process).

In the long term, OEE helps you drive improvement through a better understanding of losses. It also provides an objective way to set improvement targets and track progress towards reaching those targets.

Team Member Roles

OEE measurement is typically implemented by a cross-discipline manufacturing team and then handed over to management to drive sustained long-term improvement.

| Role | Description |

|---|---|

| Manager | Initiate project. Define scope. Identify best practices and ensure consistency across multiple facilities. Set and track improvement targets. Identify strategic improvement initiatives. Audit for sustainability. |

| Supervisor | Validate Ideal Cycle Times. Analyze losses across shifts and products. Prioritize improvement actions. |

| Operator | Capture reason codes. Drive improvement by looking for incremental opportunities to reduce loss during the shift. |

Key Insights of OEE

Start with Manual OEE Measurement

Performing manual OEE calculations reinforces underlying concepts and provides a richer understanding of OEE. It's also relatively easy.

OEE Calculation

Only three pieces of data are needed to calculate OEE:

OEE = (Good Pieces x Ideal Cycle Time) / Planned Production Time

Availability, Performance, and Quality Calculations

With two additional pieces of data (Run Time and Total Pieces) you can also calculate Availability, Performance, and Quality.

Availability = Run Time / Planned Production Time

Performance = (Ideal Cycle Time x Total Pieces) / Run Time

Quality = Good Pieces / Total Pieces

Once you understand OEE, there are significant benefits to automating data collection. Automated systems typically provide significantly improved down time accuracy, detailed performance loss information, both real-time and historical metrics, and much richer reporting.

Focus on Production Loss

Measuring OEE is only the beginning (the foundation) of an OEE program. The real power and value of OEE comes from understanding and acting on the underlying losses (Availability Loss, Performance Loss, and Quality Loss). Take effective action to reduce these losses and your OEE score will naturally improve.

Expand to the Six Big Losses

The three OEE factors, Availability, Performance, and Quality, are associated with six losses that are extremely common in discrete manufacturing (the Six Big Losses). The Six Big Losses are an excellent framework for understanding, and most importantly, for taking action, on losses exposed through your OEE initiative.

| OEE Factor | Six Big Losses |

|---|---|

| Availability |

|

| Performance |

|

| Quality |

|

Set Incremental Targets

There are many references to world class OEE as 85% for discrete manufacturing. Should that be your goal? Probably not.

If you are new to OEE, you may find that your baseline OEE is 60% or less. Or, in the future, you may find that your OEE exceeds 85%. Either way, an effective approach is to set targets that drive solid, meaningful, and incremental improvement. Each step should be a stretch target that is achievable within three to four months. Short enough to keep people engaged, long enough to achieve significant improvement.

Monitor the Constraint

OEE should always be measured at the constraint step of your process. Whether you're filling, packing, stamping, or assembling, there will always be a single step that governs your throughput. This step is the constraint, and it is the point at which it is absolutely critical to capture all losses (for other steps measure mechanical efficiency), including:

- Internal Losses (losses within the constraint): Down Time, Changeover Time, Small Stops, Slow Cycles, and Rejects.

- External Losses (losses outside the constraint): Starved (by an upstream process), Blocked (by a downstream process).

Starved and Blocked are typically seen at the constraint as Down Time. One way to Improve the Constraint is to attribute this Down Time to the appropriate external equipment or process.

Cautiously Compare

Many companies compare OEE scores across divisions, sites, and equipment. This is usually problematic. Comparisons are only truly meaningful when comparing the same equipment running the same product under the same conditions.

Resist comparing dissimilar processes. Yes, such comparisons can provide interesting insights – but they can just as easily provide misinformation as provide good information. Instead, focus on the role of OEE as an improvement tool (e.g., trend OEE over time for a given asset).

Level and Difficulty

The Level is Foundation. OEE is a best practice for measuring manufacturing productivity. It also provides valuable insights for driving improvement (particularly through the Six Big Losses).

The Difficulty is Easy. The core concepts are relatively easy to learn and there are many readily available learning resources. There are also off-the-shelf systems for automating OEE measurement.

Rate Yourself on OEE

How good is your site at OEE? Answer ten simple questions to see how close you are to a model OEE implementation.

| Question | ✔ |

|---|---|

| 1. Do you have an ongoing OEE score for each process? | |

| 2. Do you have written standards for how to measure OEE? | |

| 3. Are Availability, Performance, and Quality calculated? | |

| 4. Are reasons assigned to all Availability Losses? | |

| 5. Is Performance based on validated Ideal Cycle Times? | |

| 6. Are losses reviewed (e.g., weekly) to drive improvement actions? | |

| 7. Do you measure the Six Big Losses (to better understand losses)? | |

| 8. Do you have a documented process for improving OEE? | |

| 9. Do you have an active incremental improvement target for OEE? | |

| 10. Is your OEE measurement and data collection automated? |

Comments or Questions?

We welcome your comments and questions. Contact us at: [email protected].