Andon

What Is an Andon?

An Andon, in the context of manufacturing, is a mechanism for ensuring that problems which occur during production are immediately recognized and resolved with long-term fixes so they do not reoccur in the future. Traditionally, an Andon consists of an Andon cord pulled by the operator to signal that there is a problem and an Andon light, which calls attention to that problem.

More important than the physical mechanism is the underlying philosophy, which is to encourage operators and supervisors to work together to find the root causes of problems and implement long-term fixes to resolve those problems.

There are different “levels” of Andons with increasing technical sophistication:

- Andon Light: The traditional Andon as described above (pull cord and light).

- Andon Board: Shows the status of multiple production lines in one central location.

- Andon System: Adds supplemental signal sources (e.g., sensors) and alerts (e.g., scoreboard).

- Andon Digital System: Integrates the concepts of Andon with digital manufacturing.

In other words, an Andon can range from a simple pull cord and light to a considerably more sophisticated system that integrate sensors, scoreboards, and even IoT devices. We will cover all of these in depth.

Origins of Andon

Most people that work in manufacturing are familiar with the word Andon, but what are its origins? There is a very interesting story behind this question.

What Does Andon Mean in Japanese?

The English word Andon is derived from the Japanese word 行灯, which loosely translates to "paper-enclosed lantern." The traditional Andon lantern was constructed with a wood frame and a washi paper windbreak cover, and it was especially popular during the Edo period of Japan (1603 to 1867).

Andons in manufacturing derive their name from the traditional Andon lantern, with the shared characteristic that both are forms of illumination.

How Was the Andon for Manufacturing Invented?

The idea behind Andons for manufacturing can be traced back to the invention of an improved power loom by Sakichi Toyoda in 1896. This loom had an innovative feature - it automatically shut down if the weft thread broke. This enabled looms to run unattended for the first time; one operator could tend to multiple looms.

Taiichi Ono, the driving force behind the Toyota Production System, started his career working at Toyoda Automatic Loom Works. As such, he was an expert in the power loom, and the design of Sakichi Toyoda’s power loom was the inspiration for one of the pillars of the Toyota Production System - Jidoka.

Andons developed at Toyota as a type of Jidoka. The Toyota Production System Guide (Toyota PLC) defines two forms of Jidoka:

- Design equipment to automatically stop when a problem occurs (mechanical Jidoka)

- Equip operators with the means to stop production when they observe a problem (human Jidoka)

The Andon is essentially human Jidoka. Plant floor operators, as experts in their domain, are permitted (perhaps even obligated) to pull the cord to stop production if they perceive a potential quality issue or some other irregularity.

Andons and Lean Manufacturing

Andons are integral to lean manufacturing. They fall under the general category of visual controls, are a key element of Jidoka (automation with a human touch), and when enhanced to function as an Andon system, are strong contributors to Hoshin Kanri (aligning strategic goals at every level).

Given that the fundamental philosophy of lean manufacturing is to relentlessly work on eliminating waste from the manufacturing process, the idea of choosing to stop the line and then keeping the line stopped seems counterintuitive. Stop the line to improve production?

Shigeo Shingo, an industrial engineer who worked extensively with Toyota while a consultant with the JMA (Japan Management Association), addresses this question directly in his book A Study of the Toyota Production System. He presents the following analogy:

Of course, this approach requires both training and trust. Training to equip your operators to make effective decisions and trust that they will exercise good judgement when making those decisions.

Basic Principles of the Andon

We can gain valuable insights into improving our manufacturing operations by exploring why the Andon has proven to be so effective.

Let’s start by breaking the Andon into three elements:

- Signal: Empower operators to stop the line because of an emergent problem (pull the andon cord)

- Alert: Make line status, especially when there is a problem, very obvious (the andon light)

- Resolve: Encourage operators and supervisors to work together to find the root cause of the problem and implement a long-term fix

These elements are core to any Andon system. But what makes them so impactful?

One of the key principles underlying the Andon is empowerment - it is the elemental purpose of the signal. By granting operators the authority and responsibility to stop the line and call for assistance, Andons increase operator engagement in the manufacturing process.

A second key principle is real-time communication - it is the role of the alert, which immediately transforms any problem into a shared focus on finding a solution. Andons provide a simple, consistent, and instantaneous mechanism for communication:

- Simplicity comes from focusing on a few key pieces of critical information.

- Consistency comes from applying visual cues in a standardized way (e.g., green is normal, yellow is slightly deviating, and red requires immediate attention).

- Instantaneous comes from operators and supervisors immediately responding to the visual cues.

A third key principle underlying the Andon is to resolve problems by seeking the root cause. The inherent value of the Andon is sacrificing short-term production (stopping the line) for long-term gains (preventing the problem from recurring).

Over time, the nature and role of Andons has evolved. Visual cues are sometimes reinforced with audible cues, while Andon lights and Andon tower lights are sometimes replaced with more sophisticated notification systems. Nonetheless, the basic principles remain the same - signal, alert, resolve.

Andon Signals

Andon signals are used by operators to indicate that there is an issue with the production line. Traditionally, Andon signals are pull cords, but buttons are also common. Whatever form the signal takes, the goal is the same - let supervisors and managers know there is a problem at the line.

What Is an Andon Cord?

An Andon cord is a rope or cable hanging along the production line that the operator pulls to stop production or otherwise signal that there is an issue. Andon cords are the traditional Andon signal mechanism in the Toyota Production System (TPS).

In TPS, it is less that the operator can pull the cord if there is an emerging issue on the line (a choice) and more that they should pull the cord (an obligation or responsibility).

What Is an Andon Button?

An Andon button is an alternative form of signal. Instead of pulling the cord, the operator presses a button. Buttons have the advantage of making it easy to select from multiple status options, whereas an Andon cord typically simply stops the line.

Andon buttons are often integrated into the base of an Andon tower light, which is collectively referred to as an Andon station.

Andon Alerts

Andon alerts notify your plant floor team when there is a problem at the line. Traditionally, Andon alerts have been lights, but audible alerts are also common. With digital transformation initiatives, alerts may also include texts or emails. Whatever form they take, the goal is the same - elevate the problem and rapidly respond.

What Is an Andon Light?

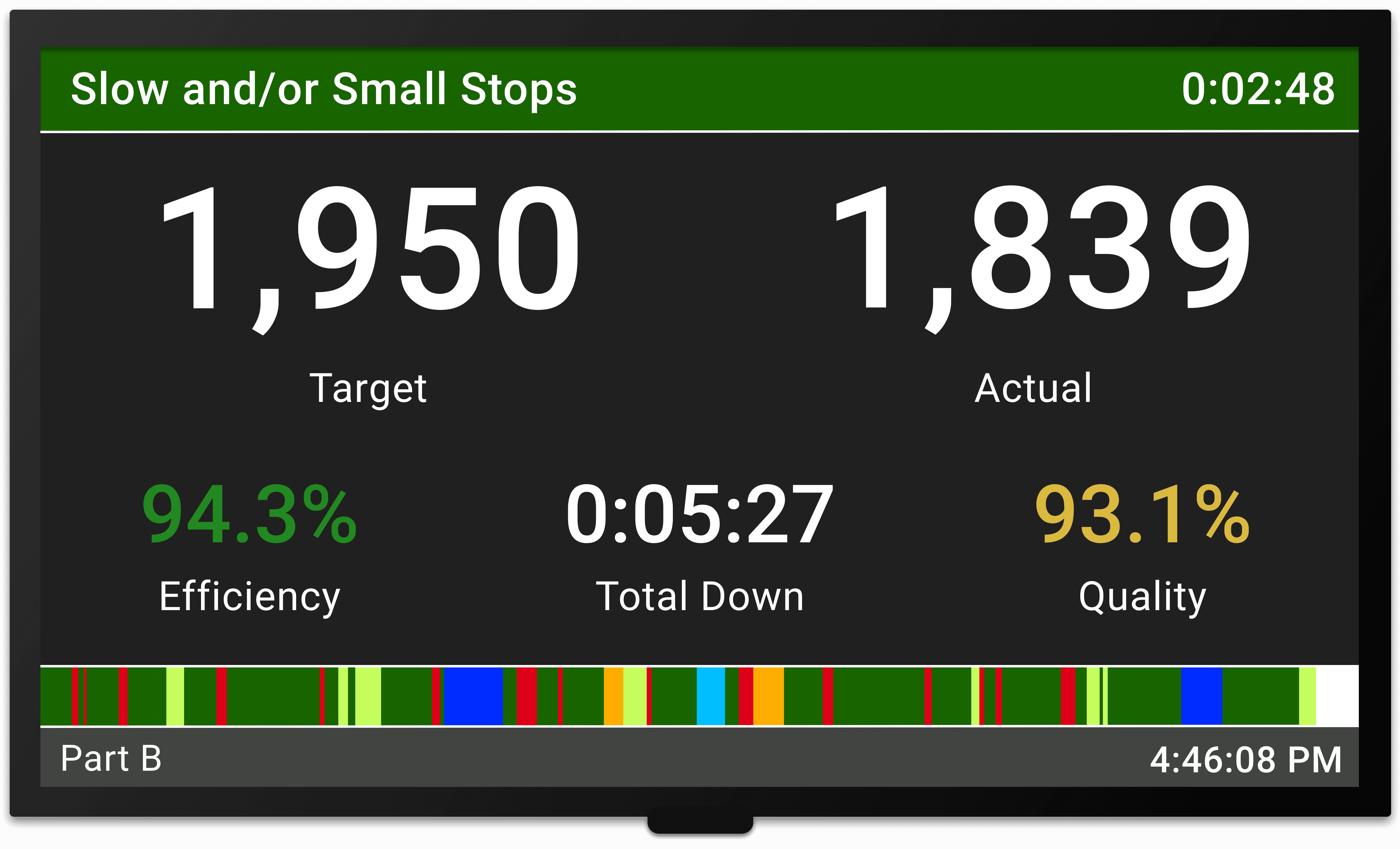

Andon lights convey the status of production lines to everyone on the plant floor. There are many different types of Andon lights, ranging from single color, to stack lights with four or more colors, to scoreboards that use color to emulate Andons.

| Andon Light Type | Description |

|---|---|

| Single Color | A single light, usually red, that indicates the line is stopped for a critical problem. |

| Stack Light | Usually three or four stacked lights that indicate that the line is stopped for a critical problem (red), needs attention (yellow), is running normally (green), or is in a planned stop (blue). Sometimes referred to as an Andon tower light. |

| Color Changing | Combines the simplicity of a single light with the expressiveness of a stack light. Uses a single RGB or RGBW LED bulb. |

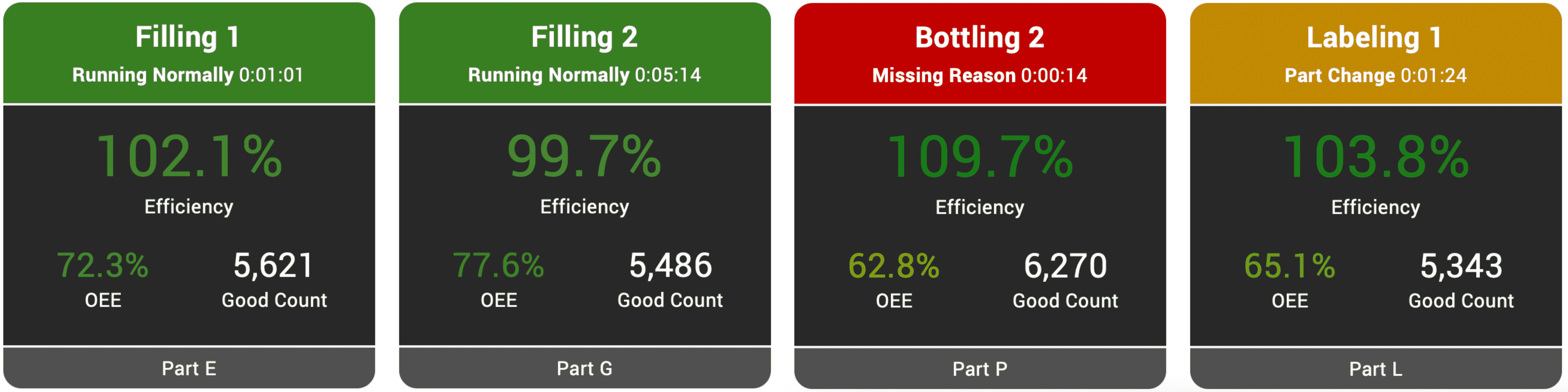

| Scoreboard | When a scoreboard uses color to clearly indicate line status, it can also be considered a type of Andon light. |

What Are Andon Colors?

Andon colors have a well-established interpretation when used as Andon lights in lean manufacturing:

- Red indicates a critical problem. The line is stopped and attention is needed immediately.

- Yellow indicates a non-critical issue. The line can run; however, the issue should be addressed as soon as possible to prevent it from potentially stopping the line in the future.

- Green indicates that there is no problem. The line is running normally.

- Blue also indicates that there is no problem. However, the line is paused for a break, maintenance, or other planned stop.

Color conventions may differ by region and culture.

What Are Andon Sounds?

Andon sounds are frequently used as a supplemental form of alert, especially to call attention to extended periods of downtime. The sound can be a buzzer, a tone, a short melody, or even a prerecorded verbal message.

Andon sounds can also be used to reinforce positive accomplishments, such as a production goal being met.

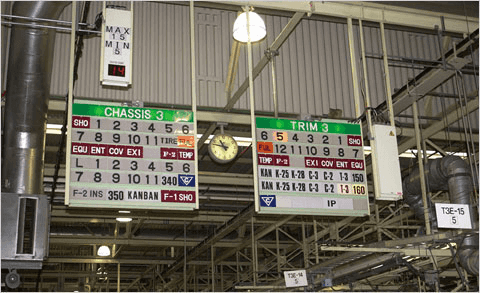

Andon Boards

A common variation on the Andon light is the Andon board, which shows the status of multiple production lines in one location.

What Is the Purpose of an Andon Board?

The purpose of an Andon board is to centralize information regarding the status of each production line, making it much easier for supervisors and managers to see which lines need attention.

Andon boards in lean manufacturing environments are usually organized as a matrix of rows and columns. Each element within the matrix represents either a manufacturing line, or a step within a manufacturing line.

Andon Systems

Are Andons still relevant in today's world of Industry 4.0 and digital manufacturing?

The answer is a resounding yes!

As discussed earlier, the core elements of the Andon, and what gives Andon meaning even today, are signal, alert, and resolve. These are universal principles that make it relatively easy to adapt the Andon to a wide range of technologies.

Furthermore, autonomation (automation with a human touch) continues not only to be relevant; it is often the optimal path for effective manufacturing. Humans are skilled observers, and the goal of an Andon system is to leverage that ability to shorten the time between a problem emerging and that problem getting resolved with a long-term fix.

Modern Andon systems leverage technology to present curated information that makes it easier to recognize emerging problems (signal), push notifications to stakeholders in real time (alert), and identify the root cause that needs a long-term fix (resolve).

Andon systems, especially in the context of digital manufacturing, make it easier to detect many issues and to call attention to those issues. However, a human touch is still essential in interpreting and acting upon this information.

Implementing Andons

The technical implementation of an Andon is highly dependent on the specifics of the signal and alert mechanisms that you choose. The simplest and fastest path is often to purchase an off-the-shelf solution.

That said, there are two areas of implementation that are universal, fundamental, and critical to success:

- Defining Standards for an Andon Implementation

- Creating a Culture of Improvement

Defining Standards for an Andon Implementation

An Andon implementation is an excellent opportunity to set clear expectations through standard work instructions that address questions such as:

- Under what circumstances should the operator immediately stop the line?

- Under what circumstances should the operator preemptively call for assistance?

- What falls within the scope of “normal operation?”

These are a set of “mutually exclusive scenarios.” In other words - all production time should fall into one of these three categories.

Another important standard related to your Andon implementation is setting a maximum amount of time to allow the production line to remain down in pursuit of a long-term fix. This can be a very sensitive topic, so it is best to address it up front. Otherwise, your operators and supervisors may feel “exposed.”

Creating a Culture of Improvement

The ultimate value of an Andon system depends on the actions it drives and the results it achieves. As in all new initiatives, it is important to establish clear expectations and create buy-in at all levels, from the plant manager through to each and every operator. Even as technology advances, people are still the key to the success of an Andon initiative.

Here are some tips for creating a culture of improvement that will help you deliver a successful Andon implementation.

Managers: Set Standards and Oversee Training

Managers should set clear expectations and create a constructive and positive environment in which operators and supervisors can suggest improvements.

- Operators need to know when and how to call attention to a potential problem and when to stop the line for an emergent critical problem.

- Supervisors need to know the maximum amount of time it is appropriate to stop the line for problem identification and resolution, and when to ask a manager for help and guidance if they are unable to find the root cause of the problem.

Managers should also ensure that operators and supervisors are thoroughly trained on policies related to the Andon implementation.

Supervisors: Encourage Operators, Respond Rapidly, and Escalate

Supervisors should encourage operators and reinforce their support for operator actions. Operators will only feel comfortable stopping the line if their supervisor supports their actions. Mistakes will be made, and in most cases, it is appropriate to handle mistakes as learning opportunities for operators.

Supervisors should rapidly respond to Andon alerts. It is important to immediately come to the assistance of operators so operators are not left exposed and so problems are resolved as quickly as possible.

Supervisors should lean on managers when a problem or proposed solution is so complex that assistance is needed. Policies can and should guide supervisors, but each situation will be different, and supervisors need to be comfortable seeking assistance from managers.

Operators: Be Proactive

Operators should proactively observe the line and take action as soon as they see a problem starting to emerge. In technically advanced Andon systems that are integrated with digital manufacturing systems, operators still have an important role to play, which is providing context when problems arise.

Benefits of Andons in Manufacturing

Andons are a highly effective tool for manufacturing. Some of their benefits are to:

- Provide a simple and consistent mechanism for communicating line status on the plant floor.

- Bring immediate attention to problems.

- Shift the focus from short-term fixes to root cause analysis and long-term fixes.

- Engage operators by increasing their responsibility for “good” production.

- Empower operators to take independent action when problems occur.

- Enable supervisors to quickly respond to manufacturing issues.

- Encourage your entire team to work together to address quality, downtime, and safety.

- Improve OEE (Overall Equipment Effectiveness) organically.

Looking to enhance your Andon capabilities or take your manufacturing processes to the next level? Vorne’s XL Productivity Appliance™ builds on the principles of Andon systems, offering real-time production monitoring, advanced alerts, and actionable insights to drive continuous improvement.