How to Reduce Machine Downtime

10 Practical Tips for How to Reduce Downtime

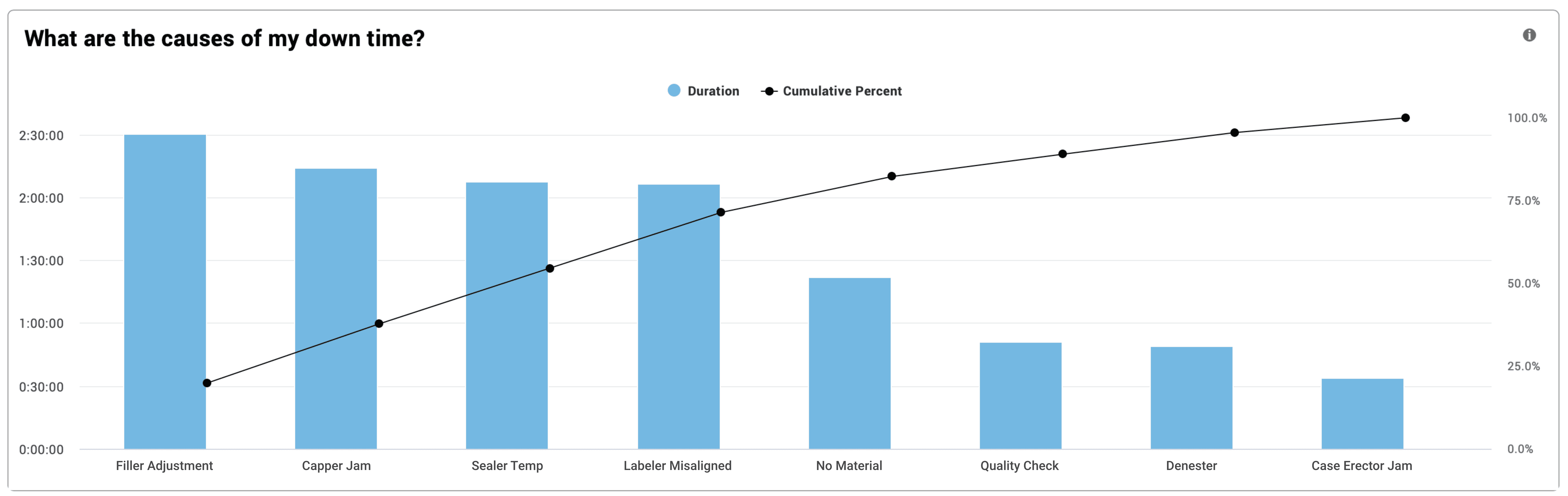

1. Capture Manufacturing Downtime Reasons

It is essential to capture a reason and a duration for each downtime event so your team can effectively interpret the data and prioritize actions. In order to create actionable data:

- Start simple, with no more than 25 reasons, one of which should be All Other Losses.

- Make sure every reason is clear on its own, as well as when compared with other reasons.

- Prefer reasons that describe symptoms as opposed to root causes so that analysis and conclusions are left in the domain of CI and engineering.

- Remove reasons that aren't regularly used, and add reasons as needed to ensure that All Other Losses is not in the top ten losses.

- Add additional detail in the form of comments for especially long downtime events.

2. Focus on the Constraint

Every manufacturing process has a constraint (i.e., bottleneck), which should be the focus of your improvement efforts. It is the point of leverage for the entire process. Measure downtime at the constraint (by automatically monitoring cycles), and Improve the Constraint to ensure that your resources are focused where they will have the greatest impact.

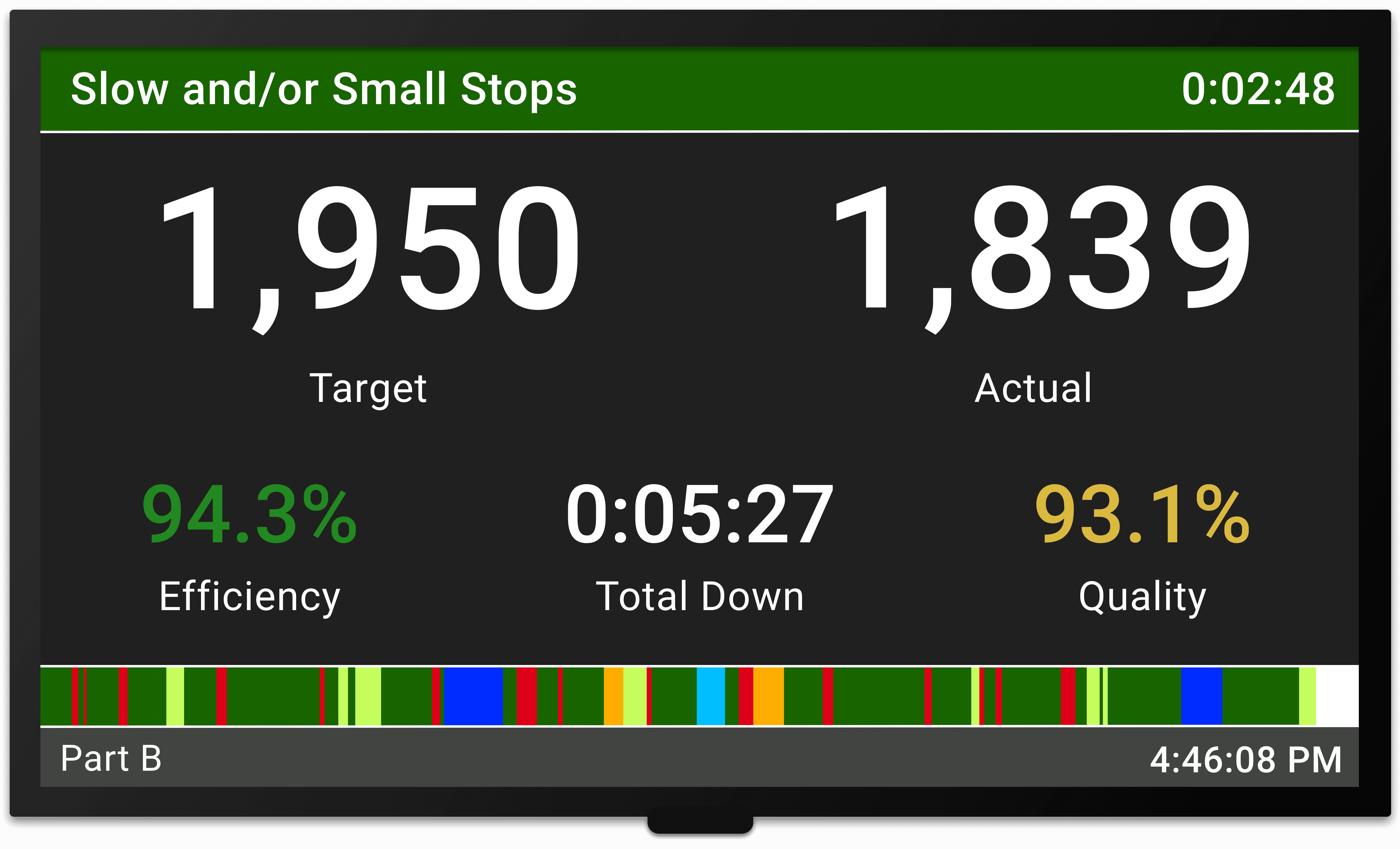

3. Treat Downtime as a KPI

Metrics that are emphasized and shared are very powerful drivers of behavior. Treat downtime as a KPI (Key Performance Indicator), and continually reinforce its importance. People love an opportunity to win, which is why we recommend a TAED scoreboard for the plant floor (Target, Actual, Efficiency, Downtime). This enables operators to track their progress in real time - and “win the shift.”

4. Make Down Events Visual

Provide clear visuals to indicate when a line is down, and escalate the message if the line remains down for an extended period of time. Train team members to react quickly, and provide multiple levels of escalation (e.g., operator, supervisor, manager). The goal is to prevent small issues from becoming large incidents, and if they do become larger incidents, to react quickly.

5. Separate Quick Fixes and 100-Year Fixes

Make a conscious decision to move forward with each downtime loss in one of two ways:

- Quick Fix: Move forward with an immediate fix that can be implemented without outside resources.

- 100-Year Fix: Escalate a problem that needs outside resources to management for a permanent fix.

6. Perform a 3S Blitz

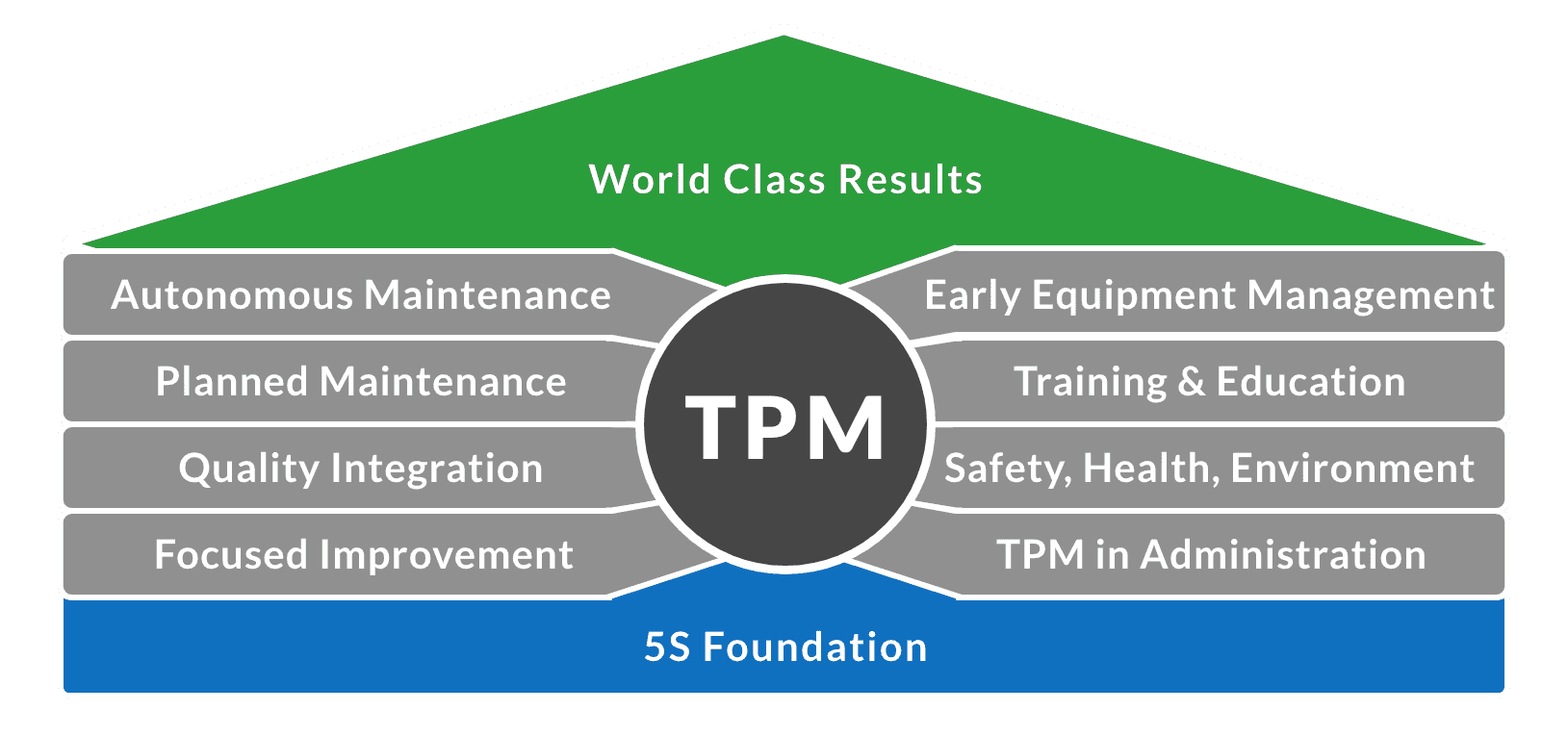

A clean and organized work environment creates better conditions for well-running equipment, which is why 5S is the foundation of TPM. A 3S blitz applies the same principles as 5S in the form of a one-off event: Sort (eliminate what is not needed), Straighten (organize what remains), and Shine (clean and inspect equipment).

7. Perform a Maintenance Blitz

Most equipment includes at least some parts that wear (e.g., seals, gaskets, bearings, belts, and rollers), which can cause breakdowns as these parts reach the end of their operational life. Check that all wear parts are in good condition, and replace any parts that are suboptimal.

8. Mark Optimum Settings

When equipment settings are continually tweaked, they are less likely to be optimal and more likely to create conditions that increase downtime. It is surprising how often this happens. Determine optimal settings as part of standard work and mark them on the equipment, making it is easy for your plant floor team to verify that the settings are as intended.

9. Perform Hourly Reviews

Every hour, hold a two-minute standup meeting at the line to review the longest downtime event (or other issue) from the last hour. Then, agree on one improvement action for the next hour. This is a simplified version of Short Interval Control.

10. Change One Thing at a Time

When fixing any loss, make one change at a time. Often, multiple changes are made at the same time without fully understanding their impact. This makes it much harder to evaluate the effectiveness of each individual action.

Benefits of Downtime Reduction

In the short term, Downtime Reduction Tips provide practical and proven ways to reduce Downtime using existing resources.

In the long term, Downtime Reduction Tips should be replaced with a structured approach to reducing Downtime, such as TPM.

Avoid Machine Downtime

Downtime Reduction Strategies

Downtime is the largest source of lost productivity for most manufacturers, and it is often the place where the fastest gains can be made. Although TPM (Total Productive Maintenance) is a clear best practice for sustainably reducing Downtime, not every company is ready to invest the time and resources to create an effective TPM program.

There are four simple strategies for reducing downtime when resources are limited:

- Track Downtime Accurately

- Categorize Downtime with Reasons

- Expose Downtime in Real Time

- Attack the Largest Sources of Downtime

You can read more about employing these strategies by visiting our How to Avoid Machine Downtime Use Case page.

Team Member Roles

Downtime Reduction Tips involve the following roles:

| Role | Description |

|---|---|

| Manager | Initiate program. Identify constraint. Select metrics. Decide when to switch focus to a more structured approach, such as TPM. |

| Supervisor | Maintain reasons. Create visuals. Escalate 100-year fixes. Mark optimal settings. Lead 3S and maintenance blitzes. Lead hourly reviews. Control change. |

| Operator | Capture reasons. Respond to visuals. Implement quick fixes and corrective actions. Verify settings are optimal. |

Key Insights into Reducing Downtime

Keep an Eye on the Big Picture

Downtime is the largest source of lost productivity for most manufacturers. It is also the most observable, involving highly visible unplanned stops. Consequently, other types of losses sometimes slip below the radar. For example:

- Frequent product changes may result in significant lost production time due to changeovers.

- Frequent small stops or slow cycles may result in significant lost production time that isn't measured.

It's important to keep an eye on the big picture. For most companies, this means implementing the gold standard for measuring manufacturing performance: OEE with a breakdown of OEE losses into the Six Big Losses, and a further breakdown of OEE Availability losses into Downtime Reasons. Add Total Effective Equipment Performance (TEEP) as a metric for insights on capacity.

Capture Improvements

Whenever an improvement is made, ask two simple questions:

- Has a new best practice been created?

- Will other teams benefit from this improvement?

If the answer to either question is yes, consider capturing the improvement as Standardized Work. This will lock in gains and ratchet up performance over time.

Shift from Reactive to Proactive

There is a big difference between working reactively (fixing problems as they occur) and working proactively (putting in long-term fixes and improvements). If most of your time is spent reactively fixing problems your progress will be limited. Reserve time for proactive improvements, and strive, over time, to shift the balance from reactive to proactive.

Consider TPM

For a comprehensive and proactive approach to reducing Downtime consider TPM (Total Productive Maintenance). TPM blurs the distinction between production and maintenance by empowering and training operators to maintain their equipment.

The scope of TPM goes far beyond Downtime. It includes a rich set of tools and processes for eliminating waste, including addressing all of the Six Big Losses. Because of its depth and complexity, a complete TPM implementation can take years, and requires strong continuing support from top management.

Level and Difficulty

The Level is Foundation. Reducing Downtime is a fundamental imperative for most manufacturers.

The Difficulty is Easy. Each Downtime Tip is designed to be straightforward to implement using existing resources.

Rate Your Downtime Reduction Strategy

How comprehensively is your site applying Downtime Tips? Answer ten simple questions to see how close you are to a model implementation.

| Question | ✔ |

|---|---|

| 1. Is a reason and duration captured for each Downtime incident? | |

| 2. Is the constraint the primary focus of improvement? | |

| 3. Is Downtime treated as a KPI (with associated SMART targets)? | |

| 4. Are Downtime incidents highly visible and escalated over time? | |

| 5. Is each Downtime incident evaluated for quick or 100-year fix? | |

| 6. Are 3S blitzes periodically organized for the work area? | |

| 7. Are maintenance blitzes periodically organized for equipment? | |

| 8. Are optimum settings decided and marked on equipment? | |

| 9. Are hourly reviews used to drive immediate improvement actions? | |

| 10. When fixing issues is one change implemented at a time? |

Comments or Questions?

We welcome your comments and questions. Contact us at: [email protected].