Andon

An Andon is a real-time visual indicator that brings attention to problems for the express purpose of addressing them as they occur with long-term fixes. Learn about Andons from the articles linked below.

Andon Topics

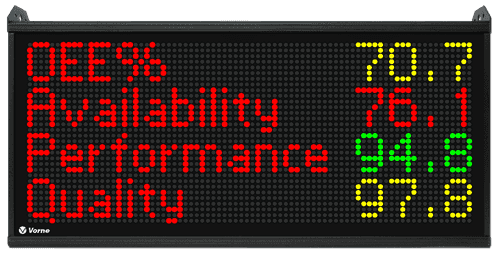

What Is Andon?

An Andon is a real-time visual indicator at the production line that is triggered by an operator to bring attention to an emergent problem with the express purpose of immediately addressing that problem with a long-term fix.

15 minute read

All Levels

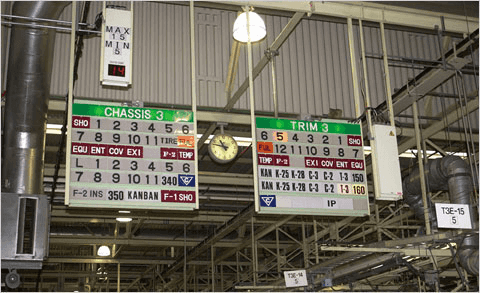

Origins of Andon

The term Andon was originally used to describe a lantern style popular during the Edo period of Japan; however, in lean manufacturing it is used to describe operator-controlled visual controls that bring immediate attention to problems in a manufacturing line.

7 minute read

All Levels

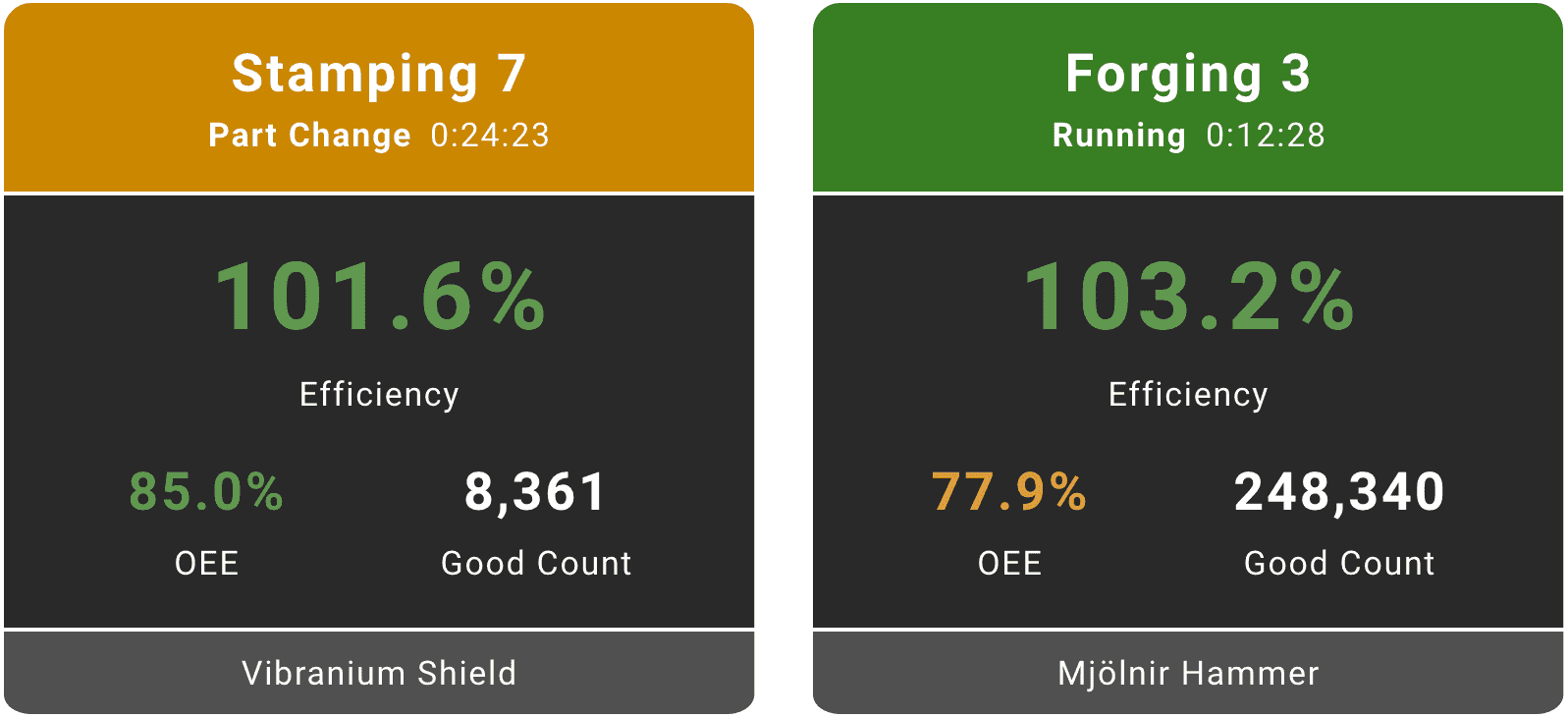

Andons In Lean Manufacturing

Andons developed as a natural offshoot of Jidoka (automation with a human touch) and quickly became an integral part of lean manufacturing with an emphasis on operator engagement, root cause analysis, and eliminating waste by aggressively attacking problems with permanent fixes.

4 minute read

All Levels

Andon Systems

Andon Systems leverage and enhance the effectiveness of traditional Andons by harnessing state-of-the-art technologies to signal issues in real time, immediately alert stakeholders to those issues, and make it easier to resolve them with long-term fixes.

8 minute read

Tactical